One of the best ways to gain insight into the design thinking process is to create some sort of prototype. This method creates an early, cheaper, reduced version of the product to reveal current design issues. Prototypes give designers the opportunity to realize their ideas, test the utility of their current designs, and explore how user samples think and feel about their products.

Prototypes are built so that designers can think of their solutions in a different way (tangible product rather than abstract ideas), as well as fail quickly and economically so that less time and money is invested in an idea that turns out be a bad one.

Here we figure out some instructions or principles before makes a good prototype.

1. Understanding the purpose of the prototype

If it's a functional prototype or a practical prototype for mechanical testing, the company needs a product that can accurately simulate the functioning of real components. It must be of the same material and have the same physical properties. However, its appearance is not much noticed.

At the same time, visual prototypes have a completely different set of requirements. Visual prototypes do not need to be functional, but there are times when they need to convey a functional appearance in a way that appeals to potential users, customers, or investors. In other words, the visual model is not pasted with tape.

2. Representation of the part

when developing a prototype, the product should be refined as much as possible — but only in a way that reflects the possibilities and limitations of the chosen production methods. Machining away some excess material may only take an hour on a prototype, but that could equate to weeks of labor during production.

3. High Finish

It may seem counterintuitive to focus on the appearance of a prototype, but the addition of a professional surface finish can provide several benefits. Besides making the prototype look more like a finished product, a professional surface finish can hide the evidence of cost-saving practices used during prototyping.

4. Add a company logo or text

For prototypes that will be shown to third parties such as customers and potential investors, a company name or logo can improve appearances and give a lasting reminder of exactly who has developed the product.

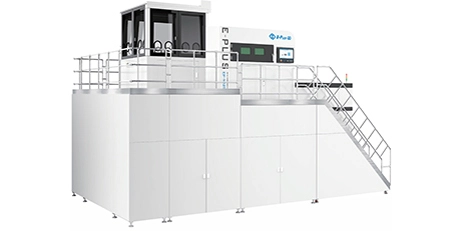

Eplus3D was founded in 2014, dedicated to the research and development and promotion of industrial-grade 3D Printing (Additive Manufacturing) systems and application technologies.