3D printing, known as additive manufacturing, creates objects by printing layer by layer. It can be applied to a variety of materials, such as polymer resin and metal.

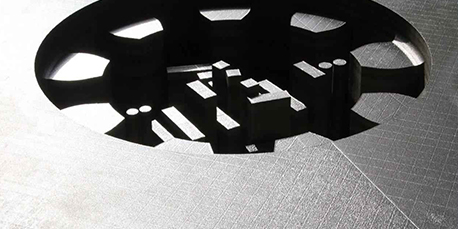

CNCPrinting, also known as subtractive manufacturing, is quite different from 3D printing. The process usually starts with a solid block of material, and then uses various tools to remove the material and shape the part. CNC machining materials include wood, plastic and metal. It is currently one of the most popular and mature manufacturing methods, suitable for small and medium-to-mass production.

CNC machining vs 3D printing differences

The main difference between 3D printing and CNC printing is that they work differently. 3D printing is an additive technology, while CNC is a subtractive technology. As we all know, 3D printing is easier to use than CNC additive machining. When the file is ready, you only need to select the part orientation, fill and support as needed. Then start to print. There is no need for a supervisor to supervise the whole process of printing. However, CNC is a labor-intensive process. It requires both skilled operators and different tools. It also requires complicated post-processing.

CNC machining vs 3D printing similarities

The answer is yes. Both 3D printing and CNC printing involve 3D files and can also produce robust and fully functional parts. In addition, the finished product after 3D printing may require a little machining to meet the standard of use when it is post-processed.

What are the benefits of combining 3D printing and CNC printing?

First of all, the combination of the two technologies will be a way to save production time and cost. The utilization rate of 3D printing materials is unmatched by CNC printing. CNC printing is a subtractive manufacturing, which means that many materials cannot be reused, resulting in a waste of materials. The two technologies can improve productivity and material utilization through different division of labor and requirements.

Secondly, combining these two manufacturing technologies can realize new design solutions. The combination of additive manufacturing metal 3d printing can further promote the progress and development of design. Especially 3D printing will provide you with new design freedom. Certain geometric shapes cannot be processed by CNC printing because of the limitations in CNC printing when designing the parts. Compared with CNC, 3D printing has few geometric restrictions. Through 3D printing it will complete hollow and complex geometric shapes.

Although both methods are very effective and useful techniques, the material, geometric complexity, manufacturing volume and budget should also be taken into consideration for the perfect performance. Please contact Eplus3D and we will tailor the most suitable solution for you according to your specific needs.