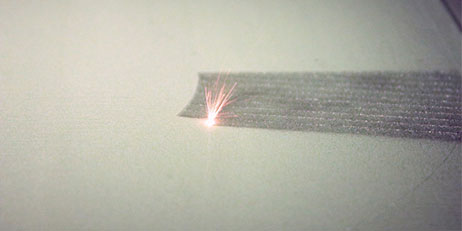

Metal 3D printing technology provides new opportunities for the development of superalloy. Superalloy are commonly used to manufacture components withstanding high-temperature environments such as gas turbines, jet engines, and aerospace engines, which require complex internal structures. Metal 3D printing technology print these complex internal structures directly, thereby improving the performance and efficiency of parts.

To date, there are several types of superalloy material that can be printed by metal 3D printer, including:

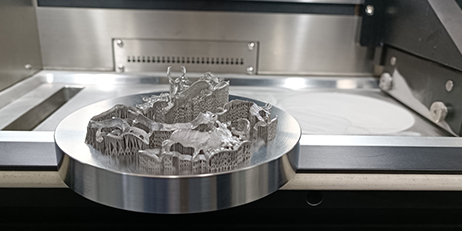

Aero-engine printed by EP-M650 with IN718

Cast superalloy: it is currently the most widely used superalloy and can be used to manufacture components in high-temperature environments such as gas turbines and aero engines. Commonly used casting superalloy include Inconel 718, Inconel 625 and Waspaloy.

Powder superalloy: it is a superalloy manufactured by sintering the mixing metal powder. Powdered superalloy produce complex components fast and they came with high density and mechanical properties. Commonly used powder superalloy include Hastelloy X, Rene 95 and CMSX-4, etc.

Metal-matrix composites: Metal-matrix composites are superalloy made by metals, ceramics and with other materials. Metal-matrix composites are with high hardness, strength and wear resistance, and can be used to manufacture components and tools in high temperature environments. Commonly used metal-matrix composites include Tungsten Carbide Cobalt (WC-Co) and Tungsten Carbide Nickel (WC-Ni).

Cartridge receiver printed by EP-M650 by IN718

Superalloy have a wide range of applications, mainly in the following areas:

In aerospace field, superalloy are widely used in components in high temperature environments such as aero engines, gas turbines and turbines.

In energy field, superalloy are increasingly used in oil and gas industry, such as oil drill bits and drill heads, components used in high-temperature environments.

In chemical industry, superalloy are used to manufacture corrosion-resistant and high-temperature-resistant equipment, such as reactors, steam generators and distillation towers.

The development and application of superalloy will mainly focus on the following directions in the future:

The performance of the strength, corrosion resistance and high temperature stability of superalloy could be even better. It can be realized by improving the alloy formula and improving the heat treatment process.

As an industry-leading provider of metal additive manufacturing solution, Eplus3D has achieved well known R&D results in various types of high-temperature alloys, including IN625, IN718, WC-CO, Hastelloy X, etc. Want to learn more? Please feel free to contact us now!