In recent years, the healthcare industry has witnessed a remarkable transformation, thanks to advancements in technology. One area that particularly stands out is additive manufacturing, commonly known as 3D printing. Among the various 3D printing techniques, Selective Laser Melting (SLM) metal printing has emerged as a game-changer in medical manufacturing. This cutting-edge technology allows healthcare professionals to create highly complex and customized medical devices, implants, and prosthetics with unparalleled precision and efficiency. In this blog, we will delve into the capabilities and potential of SLM metal printing and explore how it is revolutionizing healthcare as we know it.

What is SLM Metal Printing?

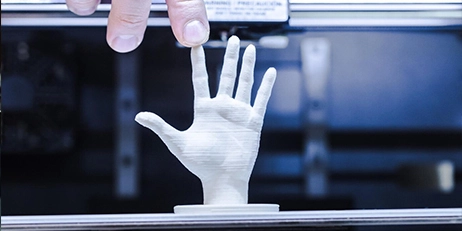

SLM metal printing is an additive manufacturing process that utilizes a high-powered laser beam to selectively melt and fuse metal powder, layer by layer, to create solid objects. It offers exceptional design freedom and allows for the fabrication of intricate and complex geometries that were previously unattainable using traditional manufacturing methods. With SLM metal printing, medical device manufacturers can produce patient-specific implants and prosthetics with exact dimensions and optimal surface finishes, ensuring perfect compatibility and function.

Advantages in the Healthcare Industry

The implementation of SLM metal printing in the healthcare industry has numerous advantages that significantly impact patient care and treatment outcomes. Firstly, the ability to manufacture personalized medical devices based on patients' scans or specific anatomical features is a major breakthrough. This level of customization results in improved patient comfort and better overall treatment outcomes, as devices can be precisely tailored to the patient's unique requirements.

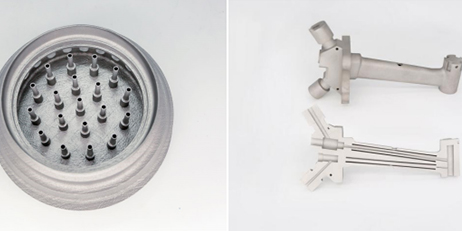

Additionally, SLM metal printing enables the production of lightweight yet incredibly strong implants. By using materials like titanium or cobalt-chrome alloys, medical manufacturers can create implants that mimic the mechanical properties of natural bone or joint structures. This not only enhances patient mobility but also reduces the risk of implant rejection or complications.

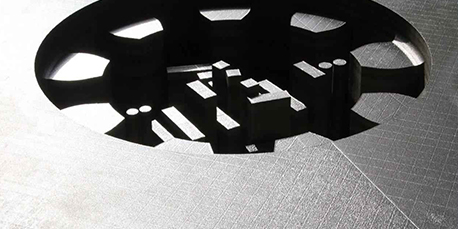

Complex Designs and Improved Functionality

In traditional manufacturing, complex designs are often challenging and costly to produce. However, with SLM metal printing, complex designs become feasible and cost-effective. Medical devices such as surgical instruments and implants can be created with intricate internal structures, enabling better performance and functionality. Additionally, SLM metal printing supports the incorporation of porous structures into implants, promoting osseointegration, the process by which bone grows into the implant, leading to better fixation and long-term stability.

The enhanced functionality provided by SLM metal printing extends beyond implants. The technology enables the creation of patient-specific surgical guides, cutting jigs, and anatomical models that aid surgeons in preoperative planning, resulting in more precise surgeries and reduced operative times. This not only benefits patients but also reduces costs for healthcare systems by minimizing the risk of complications and the need for revision surgeries.

Future Opportunities and Challenges

As SLM metal printing continues to advance, the healthcare industry can expect even greater opportunities and challenges. Research is already underway to explore the use of SLM metal printing for organ and tissue engineering, which could potentially revolutionize the field of regenerative medicine. However, challenges such as biocompatibility and the long-term behavior of printed materials within the body need to be overcome.

Furthermore, the high cost of SLM metal printing equipment and the scarcity of skilled technicians are currently limiting widespread adoption within the healthcare industry. However, as technology evolves and becomes more accessible, these barriers are likely to diminish, allowing more healthcare providers to leverage the benefits of SLM metal printing.

In conclusion, SLM metal printing represents a significant advancement in healthcare manufacturing, offering unmatched customization, intricate designs, improved functionality, and ultimately, better patient outcomes. As this technology continues to evolve and become more accessible, we can expect further advancements in healthcare, paving the way for a future where individualized care and precision are the norms.