An Introduction to SLM Metal Printing

In recent years, additive manufacturing has revolutionized the industrial landscape, and one technology that has gained significant attention is Selective Laser Melting (SLM) metal printing. This cutting-edge manufacturing method offers a range of exciting features and advantages for industries requiring high-quality metal components. From aerospace applications to medical devices, SLM metal printing is rapidly transforming the way we design, develop, and produce metal parts.

How SLM Metal Printing Works

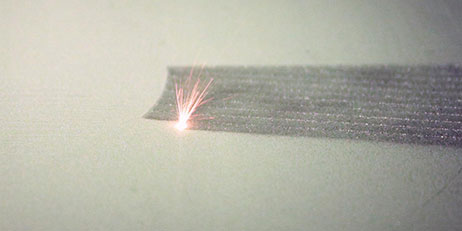

At its core, SLM metal printing involves using a high-powered laser to selectively melt layers of metal powder, gradually building up the desired component. The process begins with a 3D digital model, which is sliced into layers. The SLM machine then precisely fuses each layer using a laser beam according to the specifications provided, resulting in a highly accurate and detailed metal part.

Advantages of SLM Metal Printing

SLM metal printing offers numerous advantages over traditional manufacturing methods, making it an attractive option for various industries. Firstly, the ability to create complex geometries and intricate designs is unmatched. With SLM metal printing, the limitations of traditional machining techniques are surpassed, enabling the production of highly intricate and customized components.

Furthermore, SLM metal printing also significantly reduces material waste. Traditional manufacturing methods often require the removal of excess material, resulting in considerable waste. In contrast, SLM metal printing requires only the precise amount of raw material necessary for the final component, minimizing waste and optimizing production costs.

Applications of SLM Metal Printing

The versatility of SLM metal printing technology allows it to be used in a wide range of industries and applications. In the aerospace industry, where lightweight components with intricate designs are essential, SLM metal printing enables the production of complex parts that were once deemed impossible. This technology has also found considerable use in the medical field, particularly in the creation of prosthetics, dental implants, and bone replacements with tailored designs for each patient.

Moreover, SLM metal printing has proved to be advantageous in developing the automotive sector. By reducing component weight while maintaining strength, SLM metal printing enables the creation of more fuel-efficient vehicles and even the production of intricate internal structures that optimize performance.

Selective Laser Melting (SLM) metal printing has emerged as a game-changer in the manufacturing industry, offering numerous benefits that were previously unattainable. Its ability to produce complex geometries, minimize material waste, and provide customization options has made it an integral part of industries such as aerospace, medical, and automotive. As technology continues to advance, SLM metal printing is expected to push the boundaries further, opening up new possibilities for design and manufacturing across various sectors.