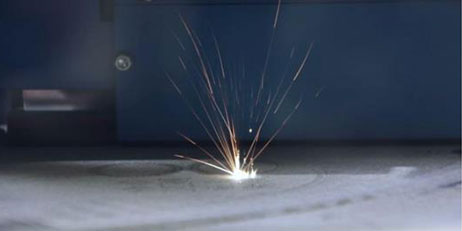

Several factors can affect the metal printing speed: powder feeding speed, scanning speed, hatching spacing and layer thickness. The quality of metal printing requires the cooperation of four parameters of laser power, scanning speed, filling spacing and layer thickness. In order to obtain good performance, the change of one parameter will inevitably cause the change of the other parameter, then the speed is affected. Today we will guide you to learn more about the four factors which can affect the metal printing speed.

Powder Feeding Speed

Powder feeding speed is an important factor affecting the overall printing speed. In order to maintain the mechanical stability of the equipment, the powder feeding speed should not be too fast as it will also affect the powder spreading effect. In order to reduce the impact of powder feeding, some metal machines use a two-way powder feeding method, which can reduce one stroke during the printing process, bringing a significant impact on the printing speed. Printers with this method often use the upper powder feeding method, and a funnel is set at the scraper to release slightly more than two powders each time.

Layer Thickness

The effect of layer thickness on printing efficiency is manifested in the fact that the layer thickness will affect the slices and squeegee stroke, resulting in the change of printing speed. Ignoring the influence of other parameters, let's compare the influence of different layer thickness on printing efficiency.

SLM layer thickness is generally 0.02mm and 0.03mm with very few exceptions. Take the following model as an example to estimate the printing time of different layer thicknesses. The height of the model is 22mm. The efficiency is calculated based on 0.02mm.

Scan Speed

After the laser power is determined, a certain scanning speed must be used to print parts with excellent performance. At the same time, there may be different parameters that can still print parts with good performance that meets the requirements, resulting in different printing speeds.

Hatching Spacing

Hatching spacing affects the printing efficiency by affecting the laser stroke. The cooperation of the laser power and the scanning speed requires the hatching spacing to be changed at the same time. Therefore, the influence of the hatching spacing on the printing efficiency can be reflected on the scanning speed.

According to the analysis, it is concluded that under the condition of fixed hardware conditions, the layer thickness is an important factor that affects the printing efficiency, but the printing layer thickness will directly affect the performance of the parts, so the appropriate choice must be made according to different applications.