Harsh environments, characterized by extreme temperatures, corrosive conditions, and high levels of stress, demand materials and components that can endure the toughest challenges. Inconel 3D printing is emerging as a game-changing technology for designing and manufacturing components that thrive in these severe conditions. In this blog, we'll explore how Inconel 3D printing is revolutionizing the way we create parts for harsh environments.

Inconel: The Ideal Alloy for Extreme Conditions

Inconel is a family of high-performance nickel-chromium superalloys known for their exceptional resistance to extreme temperatures, corrosion, and oxidation. It's a natural choice for components that must perform under harsh environmental conditions, such as those found in aerospace, oil and gas, and power generation industries.

Aerospace Components

The aerospace industry often operates in extreme conditions, with components facing high temperatures, pressure differentials, and harsh chemical environments. Inconel 3D printing is revolutionizing the sector by enabling the creation of components that can withstand these conditions, including jet engine parts, combustion chambers, and exhaust systems.

Oil and Gas Equipment

The oil and gas industry demands components that can withstand corrosive environments and high temperatures, particularly in downhole drilling and exploration. Inconel 3D printing is crucial for creating tools and components that can perform reliably in these conditions.

Power Generation

Power plants, whether they use fossil fuels, nuclear energy, or renewables, often involve extreme temperatures and pressures. Inconel 3D printing is instrumental in producing components like gas turbine parts and boiler tubes that can endure these challenges.

Complex Geometries for Superior Performance

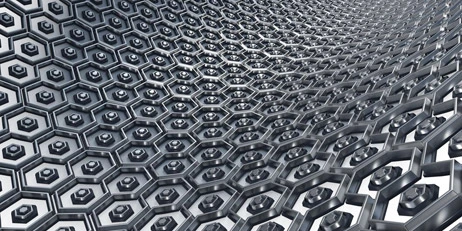

One of the standout advantages of Inconel 3D printing is its ability to produce components with intricate and complex geometries. These designs are optimized for strength, weight reduction, and performance.

Lightweighting

Designing components for reduced weight without compromising strength is a critical factor in various industries. Inconel 3D printing allows for the creation of lattice and honeycomb structures that are both lightweight and incredibly strong, making it ideal for aerospace and automotive applications.

Engineered for Efficiency

Complex geometries enable designs that maximize efficiency, whether it's improving fluid flow through complex ducts or optimizing heat transfer in heat exchangers. These designs lead to enhanced overall system performance in harsh environments.

Prototyping and Rapid Iteration

In harsh environments, precision and reliability are paramount. Inconel 3D printing offers a rapid prototyping solution for the development of components that must perform in extreme conditions. Design iterations can be tested quickly, leading to faster product development and reduced time-to-market.

Inconel 3D printing is ushering in a new era in the design and manufacturing of components for harsh environments. Its exceptional resistance to extreme temperatures and corrosion, combined with the ability to create complex and lightweight designs, makes it a key technology for industries where performance under challenging conditions is non-negotiable. As the technology continues to advance, we can expect to see even more innovative applications and designs that push the boundaries of what is possible in harsh environments. Inconel 3D printing is not just shaping the future; it's redefining the possibilities for components that can endure the extremes.