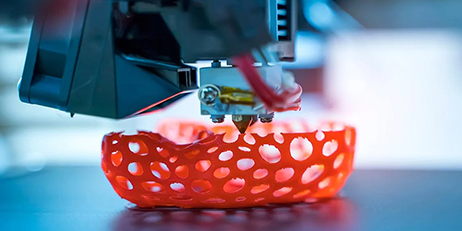

In recent years, the world of manufacturing has been revolutionized by the introduction of 3D printing technology. This innovative process allows for the creation of complex and customizable metal parts with unprecedented speed and precision. However, as the popularity of large format metal 3D printers continues to grow, concerns have been raised about the environmental impact of these cutting-edge machines and the materials they use.

The Energy Efficiency of Large Format Metal 3D Printers

One of the key advantages of large format metal 3D printers is their energy efficiency. Traditional manufacturing processes often require a significant amount of energy to produce metal parts, but 3D printing technology has the potential to drastically reduce energy consumption. By only using the exact amount of material needed for each part, large format metal 3D printers can minimize waste and lower energy usage. Additionally, the ability to create parts in-house can eliminate the need for shipping and transportation, further reducing the carbon footprint of manufacturing.

The Environmental Impact of Metal 3D Printing Materials

While large format metal 3D printers offer many environmental benefits, the materials used in the printing process can still have a significant impact on the planet. Many metal powders used in 3D printing are not recyclable and can be harmful if not handled properly. Additionally, the mining and extraction of these materials can lead to deforestation, pollution, and other environmental issues. It is essential for manufacturers to carefully consider the sourcing and disposal of metal printing materials to minimize their impact on the environment.

Sustainable Practices in Large Format Metal 3D Printing

To mitigate the environmental impact of large format metal 3D printing, companies can adopt sustainable practices throughout the manufacturing process. This includes sourcing materials from responsible suppliers, using recycled or recyclable materials whenever possible, and implementing efficient production techniques to reduce waste. Additionally, companies can invest in energy-efficient equipment and explore alternative methods for post-processing and finishing to further reduce their environmental footprint.

The Future of Large Format Metal 3D Printing and Environmental Sustainability

As large format metal 3D printing technology continues to advance, there is a growing focus on improving the sustainability of this innovative manufacturing process. Companies are developing new materials and techniques to make metal 3D printing more environmentally friendly, including biodegradable filaments and closed-loop recycling systems. By prioritizing environmental sustainability in the design and production of large format metal 3D printers, manufacturers can help minimize the impact of this technology on the planet.

In conclusion, while large format metal 3D printers offer exciting possibilities for the future of manufacturing, it is crucial to consider the environmental impact of these machines and the materials they use. By adopting sustainable practices and prioritizing environmental responsibility, companies can harness the full potential of 3D printing technology while minimizing its impact on the planet. As the industry continues to evolve, it is essential for manufacturers to prioritize environmental sustainability in order to ensure a greener future for large format metal 3D printing.