The industrialization of metal 3D printing is unstoppable, especially in the fields of military industry, aerospace and so on.

JINGYE Additive Manufacturing, as the only additive manufacturing company in the world that integrates professional R & D, production and sales of high-end aerosol metal powder, laser remanufacturing and 3D printing services, has imported the advanced metal 3d printers abroad during its early stage. Since the emergence of SLM multi laser metal 3D printer, there is an increasing demand for large-size and high-capacity additive manufacturing machines in the market, especially in the military and aerospace fields. The metal parts that need to be printed often reach the size of 300-1000mm or even larger. With the rise and maturity of domestic metal 3D printers in recent years, the new machines are products from domestic manufacturers.

Eplus3D, as a pioneer in additive manufacturing , has drawn JINGYE's attention. Recently JINGYE Additive Manufacturing has bought a batch of large metal machines from Eplus3D, EP-M650 is the most attractive one with its great performance, high efficiency and productivity.

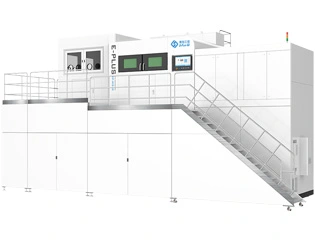

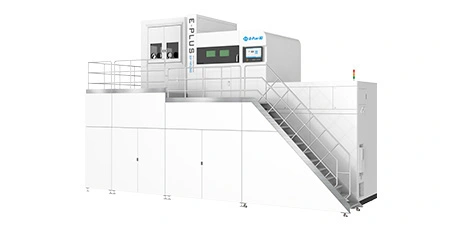

Eplus3D Quad Laser Large Size Metal 3D Printer EP-M650 installed in JINGYE Additive Manufacturing Successfully

"The first EP-M650 3D Printer arrived a few months ago and we installed it immediately, which has been continuously printing metal parts. Often one part has to be printed for more than ten days. At present, the printing success rate of our large parts is 100%, and there is no waste product. Whether it is foreign or domestic 3d printers, it is very difficult to do this, as the requirement of the stability is very high." The spokesperson of JINGYE Additive Manufacturing expressed great satisfaction with the achievements made by EPLUS3D metal 3d printer. "Continuous printing for up to 12 days without any problems in the process, requires high stability of the 3d printer. If the intermediate printing of such a large product fails, a lot of powder materials will be wasted , which may cost a lot , and seriously affect the delivery date.”

Metal Parts Printed for Aerospace (Courtesy nanjixiong.com)

"In the future, we will also deploy super large metal 3D printers with molding size of more than 1000mm, and even larger of 1800 ~ 2000mm to meet customers' increasing demand for molding size. JINGYE Additive Manufacturing attaches great importance to the development of 3D printing projects, and spare no effort to provide all-round support, promote the development of high-end manufacturing and intelligent manufacturing industry, and contribute to China's entry into a powerful country in science and technology."

(Courtesy nanjixiong.com)

About EP-M650

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm³ build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Aerospace Parts Printed by EP-M650:

Turbine Frame

Size: 620x150mm³ Size: 470x400x499mm³

Printing time: 240 hours Printing time: 176 hours

About JINGYE Additive Manufacturing

Hebei JINGYE Additive Manufacturing Technology Co., Ltd., subordinate to JINGYE group, is the only additive manufacturing company in the world that integrates professional R & D, production and sales of high-end aerosol metal powder, laser remanufacturing and 3D printing services. The company has established several intelligent manufacturing production lines from additive manufacturing raw materials (metal powder) production to laser cladding repair, 3D printing products and powder tool and die steel production to fully meet the personalized needs of customers.

About EPLUS3D

Eplus3D, founded in 2014, the core R&D teams have more than 20 years of AM expertise. Currently, it is considered as one of the most valued metal AM solution providers in the Chinese market by the industry. Till now, our industrial AM systems (MPBF/SLS/SLA) have been installed in more than 30 countries. As the company continues to invest in metal printing, EPLUS3D has a comprehensive metal AM product line that covers different kinds of applications, including but not limited to aerospace, energy, automotive, tooling, medical, dental etc.