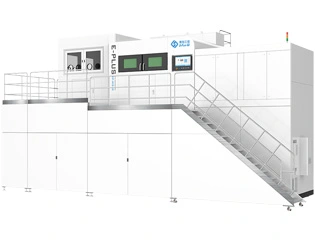

Eplus3D's introduction of the EP-M1550 and EP-M1250 metal PBF machines revolutionizes the field of large-format metal 3D printing. By offering an unparalleled building size, advanced laser technology, metal material versatility and exceptional precision & quality. The EP-M1550 and EP-M1250 pushes the boundaries of what can be achieved in the realm of metal additive manufacturing. Eplus3D continues to drive innovation in the field, establishing itself as a leader in the rapidly evolving world of metal 3D printing.

About EP-M1550:

EP-M1550 is using a large building envelope and 16-laser system to ensure high-efficiency production. The multi-laser precise positioning and innovative area splicing control technology offer uniformity and stability throughout the whole printing phase.

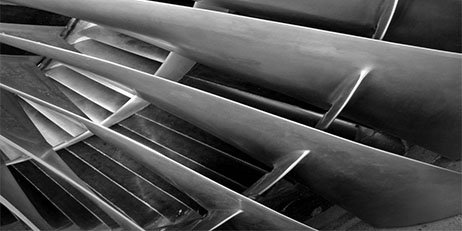

Compatible with titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, and cobalt chrome, etc. EP-M1550 is an ideal choice for direct manufacturing of large-size, high-precision, and high-performance parts for aerospace & aviation and other industries.

About EP-M1250:

EP-M1250 is an exceptional and robust metal 3D printer that makes the production of reliable and high quality large metallic parts viable on industrial scale without requiring any tools, which paves the way to industrialized serial production and integrate fully into supply chain. EP-M1250, featuring 1250 x 1250 x 1350 mm build envelope and 9-laser systems, will increase the potential for multi-meter metallic part development greatly and achieve highest productivity and reliability, which is truly the dawn of a new era in metal additive manufacturing.