Introduction

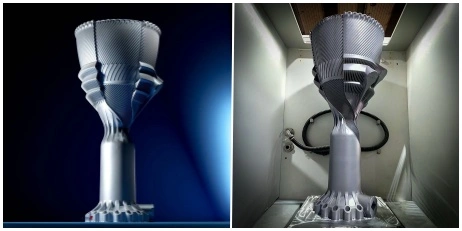

Eplus3D and LEAP 71, long-time collaborators in metal 3D printing and Computational Engineering, recently marked a significant milestone with the joint production of the world's largest single piece 3D-printed rocket thruster.

Challenging Design

The 200 kN thruster stands more than 1.3 meters tall and was designed by LEAP 71 using the Noyron Large Computational Engineering Model. Noyron distills engineering knowledge, logic, physics, and manufacturing constraints into the first computational AI for the design of complex machinery.

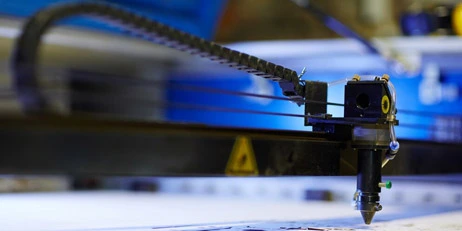

The 200 kN thruster, powered by cryogenic liquid oxygen and kerosene, is a distant relative to the Noyron TKL-5 rocket engine LEAP 71 successfully hot fired in June — but is 40 times more powerful. It combines previously separate components into one bold design. It was additively manufactured from AlSi10Mg, a high-performance aluminum alloy, on an Eplus3D EP-M650-1600 Metal Powder Bed Fusion (MPBFTM) printer using six 500 W lasers.

The engine in the unpacking station at Eplus3D’s Beijing facility

Josefine Lissner, Managing Director of LEAP 71, said: “LEAP 71’s computational models can design space hardware autonomously without the use of CAD. But limitations of current Additive Manufacturing (AM) processes, including the small build volumes of most industrial 3D printers, have continued to hold us back. I commend Eplus3D for pushing the limits, not only in print size, but also in terms of repeatability of high-quality end results, that exceeded our expectations.”

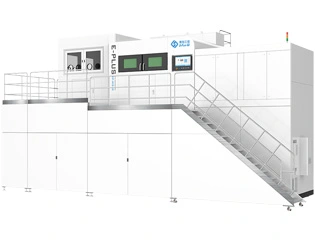

The massive 650 x 650 x 1600 mm build volume of the EP-M650H printer enabled LEAP 71 to design a fully integrated thruster geometry that Eplus3D manufactured in one uninterrupted print process, that lasted 354 hours.

Technical Innovation

Traditionally, rocket thrusters are made up from many parts, all of which need to be assembled, sealed against hot gases, and individually quality assured. The demonstrated thruster integrates all engine components, including the combustion chamber, nozzle, cooling channels, manifolds, as well us structural elements into one 3D-printable part.

The engine was manufactured from AlSi10Mg, a high-performance aluminum alloy. Aluminum is a challenging material for propulsion applications, because its low melting and reactivity to oxygen.

The rocket motor uses a dual heat-management strategy — with cryogenic liquid oxygen regeneratively cooling the main combustion chamber and kerosene fuel for the upper part of the nozzle. A layer height of 60µm was chosen to minimize the roughness of the channel walls to reduce the pressure loss due to friction.

200 kN Thruster

Pioneering the Future of Aerospace with Metal 3D Printing

The successful production of this rocket engine demonstrates Eplus3D's prowess in printing large and intricate parts. It further underscores the extensive expertise in process R&D. By precisely tuning the printing parameters for high-performance materials, Eplus3D has elevated print accuracy and surface quality to very high levels, resulting in a finished product that exceeded the quality requirements of the thruster, without the need for post-processing.

The achievement marks a significant milestone in the advancement of 3D printing technology, particularly for the aerospace industry. The successful cooperation between LEAP 71 and Eplus3D showcases the power of Computational Engineering in designing functionally integrated machinery with intricate structures that can only be realized through Additive Manufacturing. This breakthrough in tight integration between design and manufacturing not only accelerates the development of advanced aerospace components and systems but also opens new possibilities for innovation in other industries.

You will be able to see the 200 kN thruster at Eplus3D booth: Hall 12.0, Booth E101 at the Formnext 2024! Together, let’s make your ideas take shape.

About LEAP 71

LEAP 71 is a global technology company headquartered in Dubai, UAE, pioneering the emerging field of Computational Engineering. Through advanced software algorithms, the company autonomously designs complex physical products. At the core of LEAP 71’s innovation is Noyron, a Large Computational Engineering Model that enables the rapid creation of sophisticated machinery without manual input.

In June 2024, LEAP 71 achieved a significant milestone by successfully test-firing a 3D-printed liquid-fuel rocket engine designed entirely using Noyron, demonstrating the transformative potential of its approach. Collaborating with global partners, the company is accelerating innovation across industries such as aerospace, electric mobility, and thermal systems.

For more information, visit: https://leap71.com

About Eplus3D

Since founding the first PBF machine in China in 1993, Eplus3D is engaged in research and development of industrial-grade Additive Manufacturing systems and application technologies using with MPBF™ (Metal Powder Bed Fusion) and PPBF™ (Polymer Powder Bed Fusion) 3D printing technology. Eplus3D provides professional application solutions for the fields of aerospace & aviation, energy, oil & gas, automotive, tooling, healthcare, consumer goods and precision manufacturing.

Eplus3D has four facilities in Beijing, Hangzhou, Stuttgart and Houston, with an annual scientific research investment of more than 20% of the revenue with comprehensive invention patents, utility model patents, software copyrights as well as appearance patents. It has made great achievements in the design, process, software, materials and post-processing development for additive manufacturing and has successfully implemented AM solutions at customer site in more than 40 countries and regions such as Europe, Americas, Middle East, East Asia and Southeast Asia.

For more information, visit: https://www.eplus3d.com/