Shanghai, China - May 2025 - Building on the success of its 64-laser EP-M2050 system debut at TCT Asia 2024, which set a new standard for large-format, high-speed additive manufacturing, Eplus3D has once again made waves at this year’s event. The company has achieved a transformative breakthrough in metal 3D printing: mastering the additive manufacturing of pure copper and copper alloys using advanced red-laser technology.

Copper has long posed significant challenges in additive manufacturing due to its high reflectivity to red lasers and low energy absorption. Traditional red lasers often fail to fully melt copper powder, leading to defects such as unmelted particles, voids, cracks, and inconsistent layer bonding. Additionally, copper’s exceptional thermal conductivity accelerates heat dissipation, resulting in thermal stress, warping, and part failure.

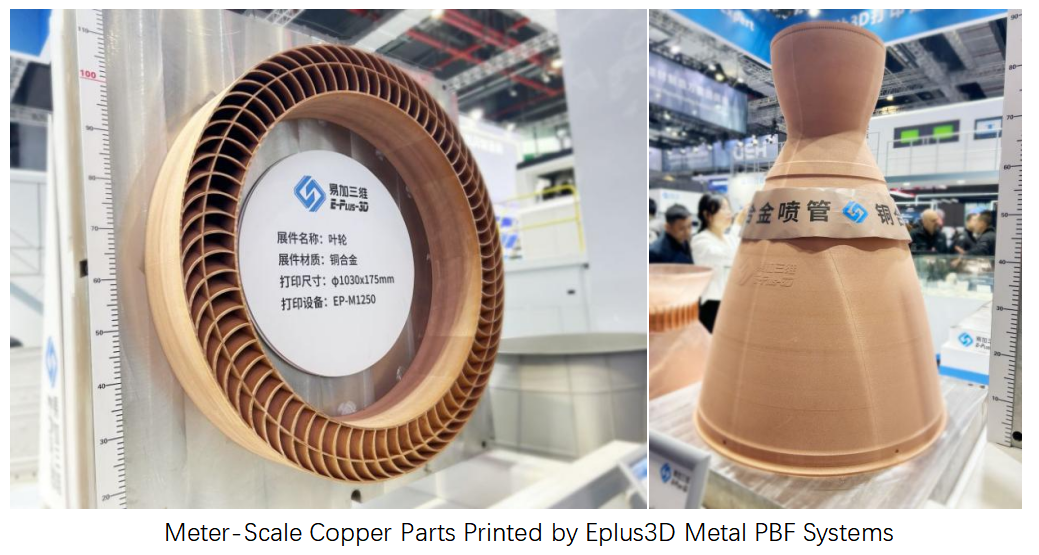

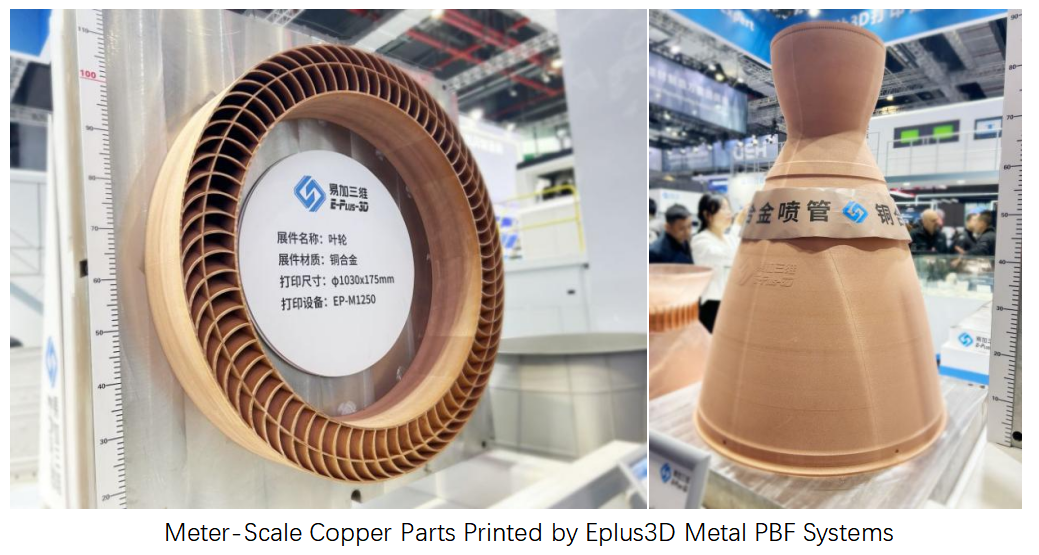

At TCT Asia 2025, Eplus3D proudly showcased multiple successful examples of meter-scale copper alloy parts, demonstrating that the company has effectively overcome these challenges- without the need for hardware upgrades. One of the standout achievements is the production of a φ1030×175 mm copper alloy impeller on the EP-M1250 system. This component boasts an impressive 99.97% density, and retains copper’s exceptional thermal conductivity- critical metrics for applications in aerospace thermal management systems.

As a leader in large-format, multi-laser metal PBF (Powder Bed Fusion) machines, including the EP-M2050, EP-M1550, and EP-M1250, Eplus3D continues to push the boundaries of metal additive manufacturing. This latest technological breakthrough ensures the stability and long-cycle reliability of meter-scale copper parts, delivering unparalleled thermal and electrical conductivity for industries such as aerospace, automotive, and electronics.

Eplus3D extends its gratitude to all visitors who stopped by its booth, shared insights, and contributed to making TCT Asia 2025 a memorable event. For those who missed the exhibition, Eplus3D invites you to join us at AMUG 2025 (Additive Manufacturing Users Group) in Chicago, Illinois, from March 30 to April 3. Visit Booth P-14 to explore the latest innovations in metal additive manufacturing and witness how Eplus3D is shaping the future of industrial production.