In metal 3D printing, support structures are crucial for components with small angles or overhangs. These structures ensure smooth printing but introduce material waste and post-processing challenges. Therefore, support-free printing holds significant value.

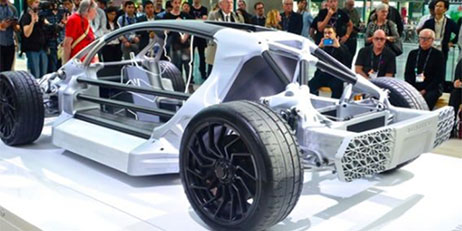

A groundbreaking aspect of support-free metal 3D printing is its capability to drastically reduce or even eliminate the reliance on support structures, which are conventionally necessary to reinforce structural components during the printing process. This advancement in metal 3D printing liberates parts from the need to be fastened to the base plate, enabling greater flexibility in layout and the creation of intricate lattice structures.

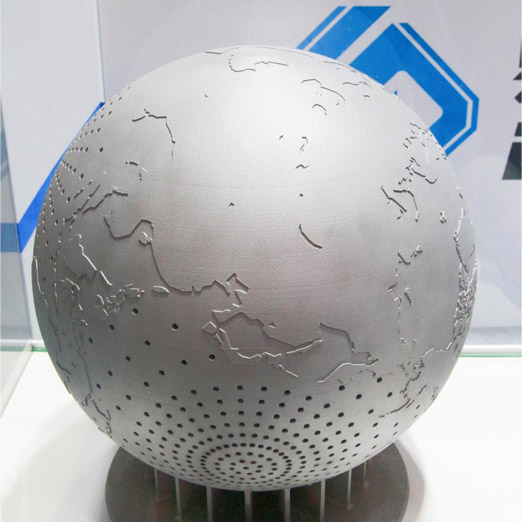

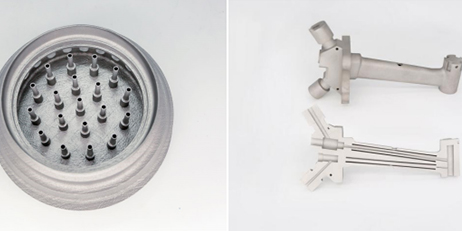

At the TCT ASIA 2023 in September, Eplus3D unveiled the groundbreaking, internally developed technology, dazzling the audience with remarkable printed objects such as Support-free Tellurion, Support-free Angle Sample, and Support-free Impeller.

Support-free Tellurion

Support-free Angle Sample

Support-free Impeller

Support-free metal 3D printing boosts printing efficiency. It reduces post-processing time and energy, optimizes metal part productivity, and reduces material usage. This lowers costs and enables industrial-scale production. Designers can create more complex designs freely. These benefits promote 3D printing's development.

Support-free metal 3D printing has emerged as a pivotal and dependable manufacturing approach for the development of next-generation rocket engines and other sophisticated space systems.