When you start to design for additive manufacturing, you also need to consider the type of materials that will be used and the number of components to be printed.

When selecting materials, one of the good rules is that if the material is easy to weld, which could be the ideal choice for powder bed fusion additive manufacturing. The most commonly used metal for powder bed fusion is maraging steel, stainless steel, aluminum, titanium, cobalt chrome, and nickel-based super alloys.

At the same time, large parts will require a large amount of powder raw materials for powder bed fusion, and if the construction fails, there is a risk of waste.

Recycling of powder feedstock is often limited because exposure to the atmosphere can cause oxidation, which can change the mechanical properties of materials, especially fatigue life. Reused powder also needs to be carefully sieved and filtered to ensure that the particle size distribution meets the specifications each time it is produced.

The last thing to consider is the size of the build machine. The size of the machine you use for production limits your ability to produce certain parts. This will also affect the speed at which parts are produced.

POWDER SIZE, SHAPE, AND TEXTURE

When it comes to powder bed fusion, the size, shape, and texture of the particles in the powder raw material are all important considerations. For example, the size of the powder affects absorption, fluidity, surface finish and characteristic dimensions, while the shape and texture strongly affect the spread-ability and other properties of the powder.

The particle size distribution is also important because it defines the size range of the particles that will melt during the powder bed melting process. If the particles are too large, the laser power may be insufficient (or the scanning speed is too fast) to completely melt the powder, which may result in lack of fusion defects. Conversely, if the particles are too small, there may be too much energy in the molten pool, which may lead to porosity and other defects.

Therefore, the process parameter settings (such as laser power, scanning speed, hatch spacing, and layer thickness) vary by material and machine manufacturer. Different machine manufacturers use slightly different powders and have fine-tuned their process parameters to ensure high-quality components. In some cases, it may take up to a year to optimize the process parameter settings for new powders or new materials.

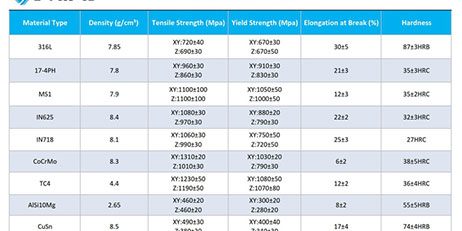

The following table summarizes the ranges of some of the material properties that are achieved by EPLUS3D on our own laser-based powder bed fusion systems. Welcome to contact us for more details about the technologies.

https://www.eplus3d.com/Additive-Manufacturing-Material/