As one of the most widely-used printing materials in aerospace, shipbuilding and medical world, Titanium alloy has excellent characteristics in high specific strength, excellent corrosion resistance, high-temperature resistance and good bio-compatibility. Yet for other industries, one of the most important reasons to not use titanium is because of the high cost of this material.

So What Makes Titanium Material so Expensive?

1. Titanium's high oxygen binding capacity makes it difficult to extract titanium from the ore, which causes relatively complicated and cumbersome extraction work. Most importantly, the key reason for the higher cost is that another expensive metal "Magnesium" needs to be oxidized to distill titanium in a vacuum environment. The entire titanium smelting is an electrolytic reduction process that requires massive electric energy. After titanium distillation, the titanium appearance is loose and porous, which is called Sponge Titanium, which must be re-melted in an electric furnace to become usable titanium ingots.

Titanium Ore:

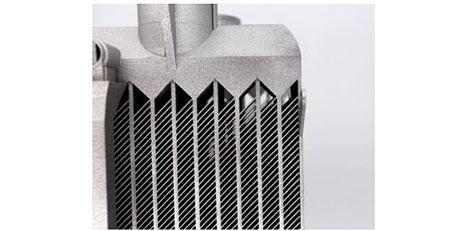

2. In addition to the difficulty of extraction, the processing of titanium is another challenge. Due to the low thermal conductivity of titanium, the titanium machining process is complicated. The main problem of cutting titanium is that the process will generate over-high heat. The poor heat transfer capability of titanium itself leads to considerable heat energy being directly transferred to the cutting edge, causing rapid wear of the cutting edge, further shortening the life of the cutting tool, and causing damage to the mold.

Traditional Titanium manufacture waste:

At present, titanium alloys are mainly produced by traditional methods such as casting and machining processing. Yet Titanium alloy products of traditional manufacturing methods usually come with porosity, composition segregation, etc., which results in poor mechanical properties. As for the machining of titanium alloys, due to the poor thermal conductivity of the material and the serious tendency of processing hardening, machining processing becomes very difficult. At the same time, machining processing generates a large amount of material waste, which will inevitably increase the cost of manufacturing.

On the other side, titanium alloy metal 3D printing is manufactured in layer-by-layer construction, which has significant advantages compared with the traditional production method of titanium alloy:

Through optimized process parameters, metal 3D printers can manufacture nearly full-density parts, reducing the occurrence of metallurgical defects.

Through layer-by-layer manufacturing, parts of any complex shape, in theory, can be produced directly, which extremely liberalizes the structural design and production flexibility.

Reduce the production processes, shorten the production cycle, and greatly improve production efficiency.

Titanium alloy products by Eplus3D metal 3D printer with complex structure and high precision.

Let alone the extraction work, metal 3D Printer is an ideal manufacture option for titanium-material processors to consider trying a new process method to reduce the processing cost. If you' re keen to save your titanium process budget, feel free to contact Eplus3D for a better production solution today!