In today's rapidly advancing technology landscape, the field of medical implant production has been revolutionized by metal additive manufacturing machines. These cutting-edge devices, such as the ones offered by Eplus3D, have paved the way for unparalleled precision and efficiency in the creation of medical implants. In this blog, we will explore the incredible capabilities of metal additive manufacturing machines and their impact on the medical industry.

The Rise of Metal Additive Manufacturing Machines

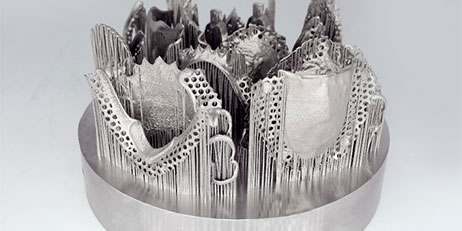

Metal additive manufacturing machines have emerged as game-changers in the field of medical implant production. Unlike traditional manufacturing methods, which often involve casting or subtractive machining, these machines utilize a layer-by-layer approach to build intricate and highly precise metal structures. This technology allows for the creation of customized implants that perfectly match a patient's unique anatomy, resulting in significantly improved implant success rates.

Unparalleled Precision and Efficiency

One of the key advantages of metal additive manufacturing machines is their ability to achieve unparalleled precision. With the power to create intricate designs and complex geometries, these machines offer a level of customization and detail that was once unimaginable. This precision is particularly crucial in medical implant production, where even the slightest deviation from the desired specifications can have severe consequences. By ensuring a perfect fit, these machines greatly enhance the implant's functionality and comfort for the patient.

Furthermore, metal additive manufacturing machines have significantly improved the efficiency of implant production. Traditional methods often involve multiple steps and complex tooling setups, resulting in longer production times and increased costs. Metal additive manufacturing eliminates many of these steps, allowing for faster production cycles and reduced expenses. This efficiency not only benefits the manufacturer but also translates into shorter waiting times for patients in need of essential medical implants.

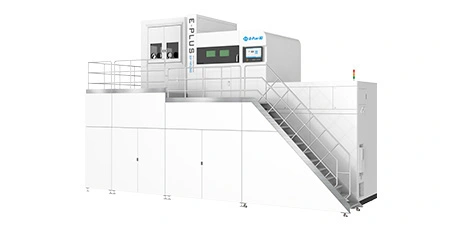

Eplus3D's Cutting-Edge Technology

As a leading brand in the metal additive manufacturing machine industry, Eplus3D is at the forefront of precision and innovation. Their advanced machines combine high-speed printing capabilities with exceptional accuracy, enabling the production of complex and detailed medical implants. Eplus3D's commitment to continuous research and development ensures that their machines remain at the cutting edge of metal additive manufacturing technology, consistently surpassing industry standards.

A Bright Future for Medical Implant Production

With metal additive manufacturing machines continually evolving, the future looks promising for medical implant production. The ability to create implants with unprecedented precision opens up new possibilities for improved patient outcomes and quality of life. From dental implants to orthopedic and cardiovascular devices, metal additive manufacturing is revolutionizing the medical industry, enabling surgeons to provide better care and customized solutions.

In conclusion, metal additive manufacturing machines have unlocked a new era of precision in medical implant production. Brands like Eplus3D are driving this revolution with their state-of-the-art technology and commitment to innovation. As these machines continue to advance, the potential for improving patient outcomes and revolutionizing the medical industry becomes even more promising. With unparalleled precision and efficiency, metal additive manufacturing machines prove to be the future of medical implant production.