Who is PWR?

PWR Advanced Cooling Technology (PWR) is headquartered on the Gold Coast, Australia. The company is renowned for its expertise in high-complexity, small-batch customized heat exchangers and supporting components, which are specially designed for motorsport and aerospace applications. With additional facilities in Indianapolis, USA, and Rugby, UK, PWR has established a global footprint. Recognizing the dynamic nature of the Additive Manufacturing market, PWR has strategically positioned itself as an early adopter of Additive Manufacturing technology. This innovative approach not only enhances their product offerings but also aligns with their expansion into the rapidly growing aerospace industry, ensuring they remain at the forefront of heat exchange solutions.

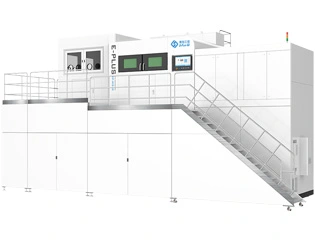

What Makes Eplus3D Stand Out as a Partner?

PWR conducted a challenging evaluation of 3D printers from leading brands, ultimately considered many different 3D printing vendors. Toby Maconachie, Additive Manufacturing Engineer at PWR, explained, "We provided the same challenge to all the vendors, and Eplus3D stood out. They not only delivered the test part the fastest, but their test part also passed rigorous pressure and leak tests, demonstrating exceptional stability and reliability. Furthermore, Eplus3D excelled in external surface finishing, achieving a design with leak tight thin tube walls and fine fin geometry, with consistently high print quality and minimal iterations required. These were the deciding factors for us to choose Eplus3D."

Innovating Aheadd®CP1 Manufacturing and Unlocking New Frontiers

In response to PWR's demand for the development of high-performance aluminium additive manufacturing powder Aheadd®CP1, Eplus3D collaborated closely with PWR to conduct process parameter development on the equipment. The successful development of the printing parameters ensures the outstanding performance of the fabricated parts, achieving an average density of 99.93%. Aheadd®CP1, in its as-built condition, offers high ductility and new possibilities for producing large components with minimal geometric deformation.

Aheadd® CP1 is a pioneering Aluminium-Iron-Zirconium powder solution designed specifically for additive manufacturing without volatile elements, rare earths, silicon or ceramic particle additions. Aheadd® CP1 was approved by the Federation Internationale de l'Automobile (FIA) for use in Formula 1 racing beginning in the 2024 season.

Optimizing Production Workflows and Strengthening Brand Positioning

As the collaboration between PWR and Eplus3D grew, the benefits became evident. Eplus3D’s solution, renowned for its high efficiency and low resource consumption, combined with its user-friendly design, enables quick and economical operations. This significantly enhances product design and manufacturing capabilities, allowing PWR to meet complex client demands. Toby noted, “This improvement in capability has brought us unexpected gains. By showcasing our diverse capabilities and tailored solutions, we inspire confidence in our customers, fostering long-term collaboration and a reliable brand reputation.”.

Pushing Boundaries of Metal Additive Manufacturing Capabilities

Toby said, "The Aerospace industry, especially in the realm of electronics cooling, is presenting new opportunities. Meanwhile, in the context of evolving technologies, we're seeing a shift towards more sophisticated cooling systems." In the pursuit of advancing Metal Additive Manufacturing applications, the engagement between PWR and Eplus3D has been a resounding success. This partnership is unlocking numerous possibilities for thermal management in the Aerospace sector, paving the way for an unprecedented era of efficiency, reliability, and customization.

This project underscores Eplus3D´s exceptional capabilities in Metal Additive Manufacturing and its dedication to advancing the boundaries of what metal AM machines can achieve.