As technology continues to advance at an unprecedented rate, the field of maintenance and repair has not been left behind. One such groundbreaking innovation is the laser metal deposition 3D printer, a technology that is revolutionizing maintenance procedures across various industries. In this blog, we will explore the importance and benefits of laser metal deposition in maintenance, with a focus on the cutting-edge brand, Eplus3D.

What is Laser Metal Deposition?

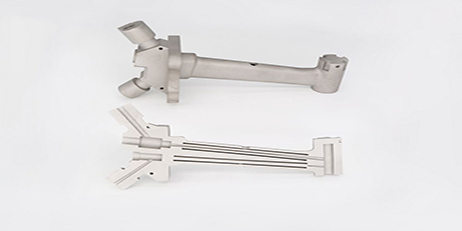

Laser metal deposition, often referred to as LMD, is a technique used to repair and restore damaged components by depositing metal layers onto the surface. This process involves the use of a high-power laser to melt and fuse metal powders, forming a strong and durable metallurgical bond. Unlike traditional repair methods, laser metal deposition 3D printers offer precise control over the deposition process, resulting in a superior repair quality.

The Role of Laser Metal Deposition in Maintenance

Maintenance plays a crucial role in ensuring the longevity and optimal performance of machinery, equipment, and parts. However, traditional repair techniques often involve expensive replacements or extensive downtime. Laser metal deposition 3D printers have emerged as a game-changer in the maintenance industry. The ability to repair damaged components on-site, without the need for replacement parts, reduces costs and minimizes production interruptions.

The Advantages of Eplus3D Laser Metal Deposition 3D Printer

Eplus3D has established itself as a leader in the field of laser metal deposition technology. Their cutting-edge 3D printers offer numerous advantages that make them the go-to choice for maintenance and repair professionals.

High Precision: Eplus3D printers utilize advanced laser systems, ensuring precise and accurate deposition of metal layers. This level of precision allows for intricate repairs, even on complex components.

Versatility: Eplus3D printers are compatible with a wide range of metal powders, making them suitable for repairing various materials and alloys. From steel to titanium, the possibilities are extensive.

Time-Efficiency: The efficiency of laser metal deposition allows for rapid repairs, significantly reducing downtime. This is crucial in industries where every minute of production is valuable.

Cost Savings: The ability to repair components instead of replacing them not only saves on material costs but also eliminates the associated expenses of purchasing new parts.

Applications of Laser Metal Deposition in Maintenance

Laser metal deposition technology finds applications in diverse industries where maintenance and repair are essential. Some notable sectors benefiting from this innovation include:

Aerospace: Laser metal deposition ensures the restoration of critical engine and structural components, reducing the need for costly replacements.

Automotive: The ability to repair worn-out or damaged engine components improves vehicle performance and extends their lifespan.

Manufacturing: Laser metal deposition can be employed to repair molds, dies, and other tooling equipment, minimizing downtime and optimizing production.

Energy: Repair and maintenance of complex machinery used in the energy sector can be efficiently addressed using laser metal deposition technology.

The laser metal deposition 3D printer is a revolutionary technology that is transforming the maintenance and repair landscape. Eplus3D, with its state-of-the-art printers, is at the forefront of this innovation. The precision, versatility, time-efficiency, and cost savings offered by laser metal deposition make it an indispensable tool in a wide range of industries. Embracing this cutting-edge technology ensures that maintenance and repair procedures are streamlined, enhancing productivity and extending the lifespan of crucial components.