On December 15, 2023, the Ministry of Industry and Information Technology (MIIT) announced the "Announcement on the Typical Application Scenarios List of Additive Manufacturing in 2023", a total of 42 items such as "arc oriented energy deposition of aerospace large high-strength aluminum alloy components" in the industrial field were selected.

Public List of Additive Manufacturing Typical Application Scenarios in 2023

(the first eight application scenarios are selected)

NO. | Application Scenarios | Scenario Enterprise Units |

I. Industry Field |

1 | Arc oriented energy deposition of large high-strength aluminum alloy components in aviation | Supplier: Capital Aerospace Machinery Co., Ltd., Shenyang Sandi Automation Software Technology Co., Ltd. User: China Aerospace Science and Technology Corporation |

2 | Aerospace lightweight porous complex thin-wall integrated manufacturing | Supplier: Beijing Spacecraft Manufacturing Co., Ltd (BSC), HANGZHOU EPLUS 3D TECH CO., LTD., Sichuan Zhongjing Aerospace Technology Co., Ltd. User: China Aerospace Science and Technology Corporation |

3 | Integrated manufacturing of aerospace meter-level key components | Supplier: HANGZHOU EPLUS 3D TECH CO., LTD., AVIC MANUFACTURING TECHNOLOGY INSTITUTE, ZHONGKEXIANGLONG LIGHTWEIGHT CO.,LTD User: China Aerospace Science and Technology Corporation |

4 | Lightweight manufacturing of aerospace complex structures | Supplier: Aerospace Additive Technology (Beijing) Co., Ltd. User: China Aerospace Science and Industry Corporation Limited (CASIC) |

5 | Mass production of key components of aerospace liquid engines | Supplier: Xi'an Aerospace Engine Co., Ltd., Xi'an Bright Laser Technologies Co., Ltd. User: China Aerospace Science and Technology Corporation |

6 | Lean production of aerospace engines key components whole process | Supplier: Luzhou Hanfei Aerospace Science and Technology Development Co., Ltd.(LHATC), Xi'an Bright Laser Technologies Co., Ltd. User: China Aerospace Science and Industry Corporation Limited (CASIC), MoreWave Technology Innovation Co.,Ltd. |

7 | Integrated batch manufacturing of aerospace engine complex components | Supplier: XI’AN AEROSPACE MECHATRONICS & INTELLIGENT MANUFACTURING CO., LTD., HANGZHOU EPLUS 3D TECH CO., LTD. User: Institute of Engineering Thermophysics, Chinese Academy of Sciences, Sichuan Aerospace Zhongtian Power Equipment Co., Ltd. |

8 | Design optimization and manufacturing of commercial aerospace turbine disc high-temperature alloy powder composition | Supplier: Jiangsu Vilory Advanced Materials Technology Co., Ltd., HANGZHOU EPLUS 3D TECH CO., LTD. User: Jiangsu Shenlan Space Co., LTD. (Deep Blue Aerospace) |

*refer to MIIT's report for more details: https://www.miit.gov.cn/zwgk/wjgs/art/2023/art_30fdccf5abed43199ee7f7aec8fad42a.html

As an additive manufacturing machine supplier, Eplus3D is involved in four application scenarios of the top eight application scenarios in the industrial application field in this announcement. These include aerospace lightweight porous complex thin-wall integrated manufacturing, integrated manufacturing of aerospace meter-level key components, integrated batch manufacturing of aerospace engine complex components, design optimization and manufacturing of commercial aerospace turbine disc high-temperature alloy powder composition. The users include China Aerospace Science and Technology Corporation, Institute of Engineering Thermophysics, Chinese Academy of Sciences, Sichuan Aerospace Zhongtian Power Equipment Co., Ltd. and Jiangsu Shenlan Space Co., LTD. (Deep Blue Aerospace) etc.

Through the publicity, we can see that on the one hand, the aerospace field is still the most typical application field in the additive manufacturing industry. This is because industrial-grade metal 3D printers can directly manufacture complex parts with large size, high precision and high performance, such as turbine blades, heat exchangers and structural components, which are difficult to be produced by traditional manufacturing processes. From complex turbine blades to lightweight structural components, MPBF system is enabling aerospace manufacturers to achieve more goals, allowing for rapid prototyping and part production, reducing delivery times and costs, while maintaining the highest quality and safety standards.

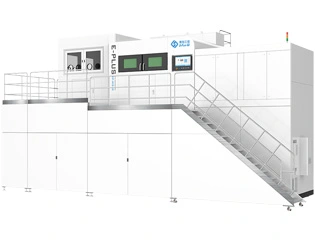

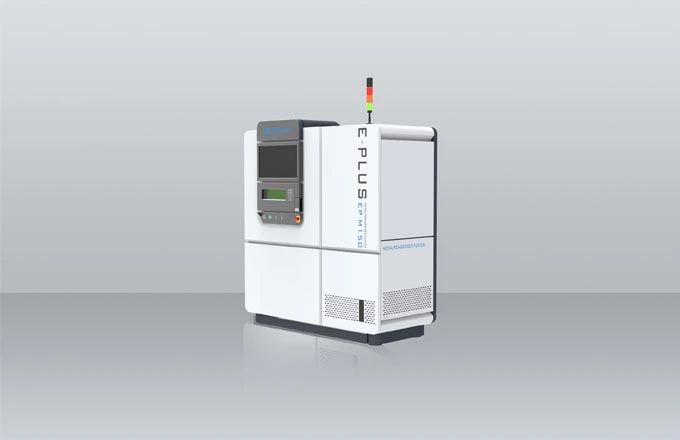

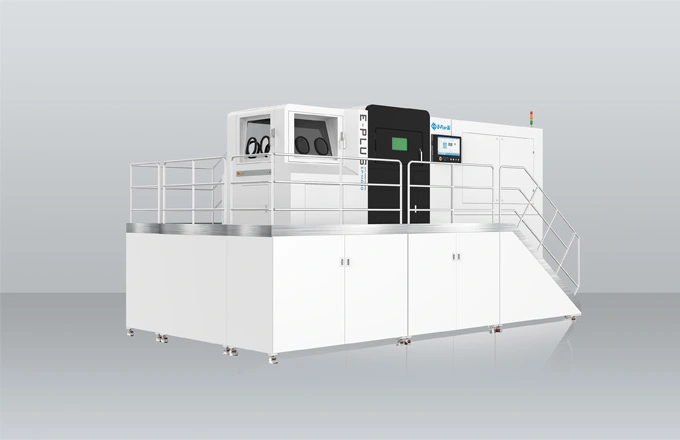

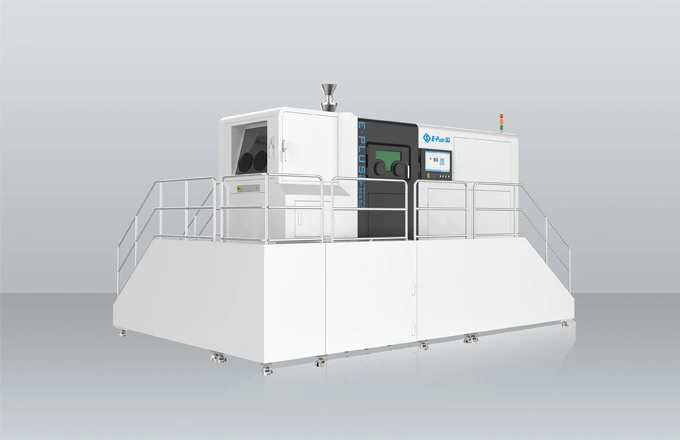

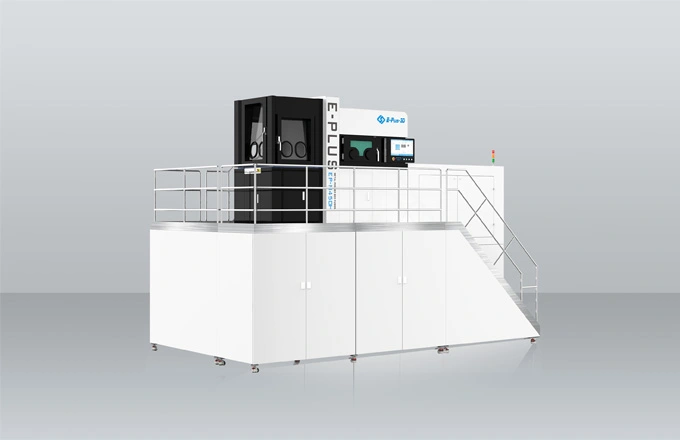

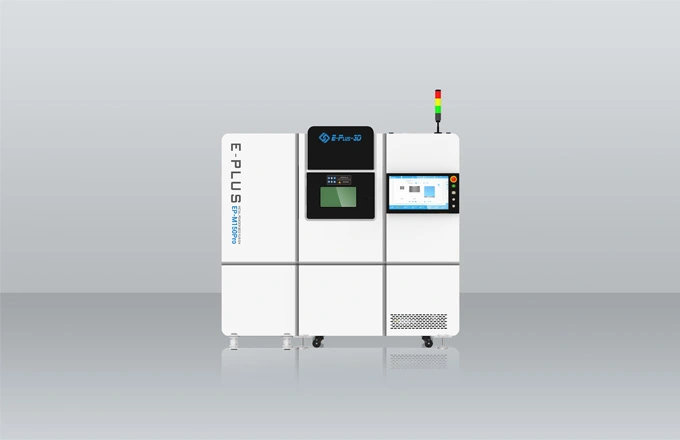

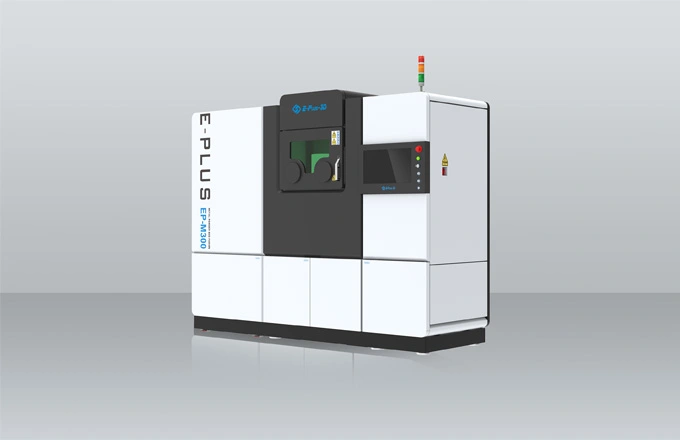

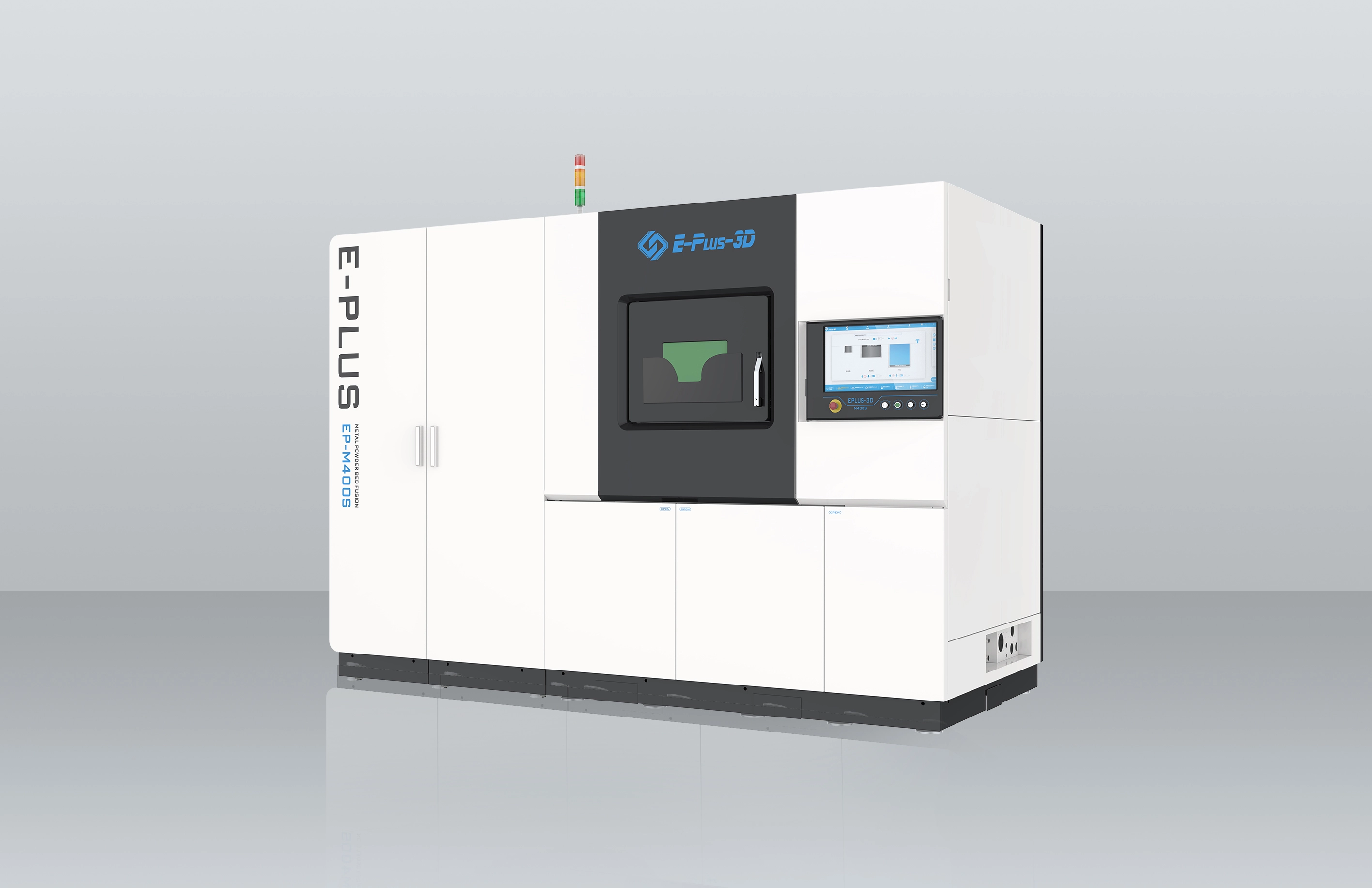

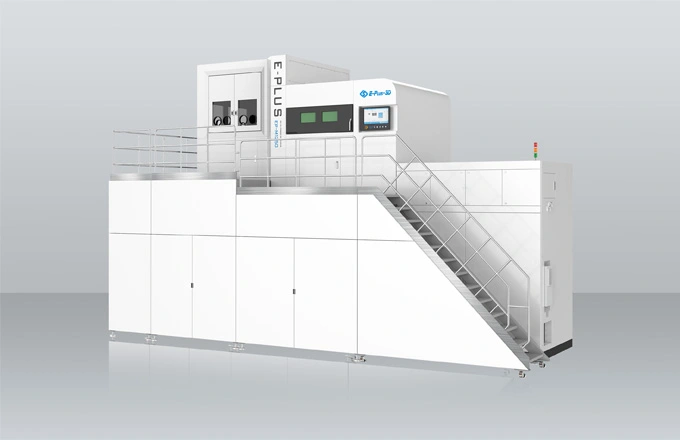

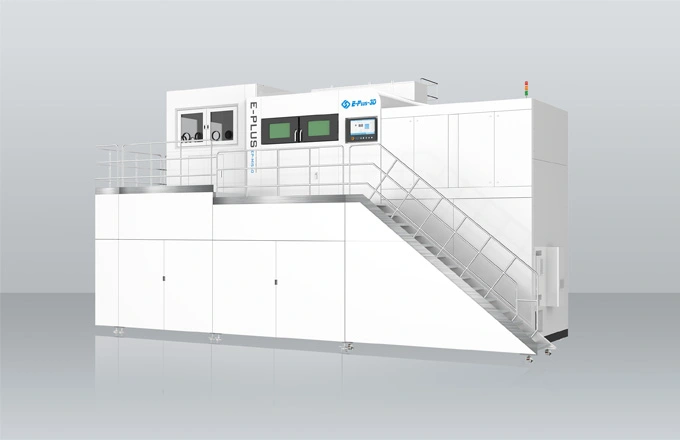

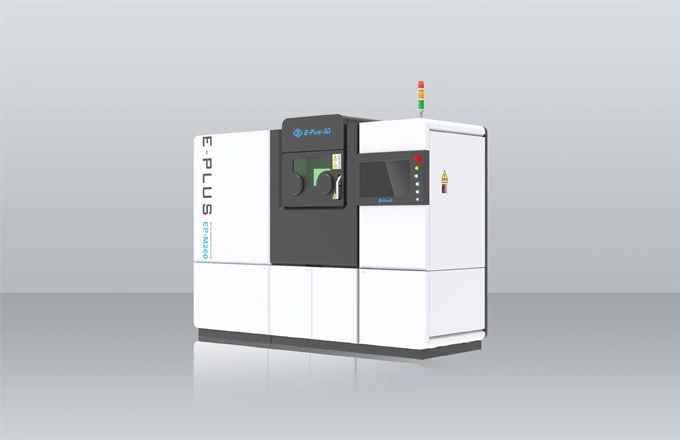

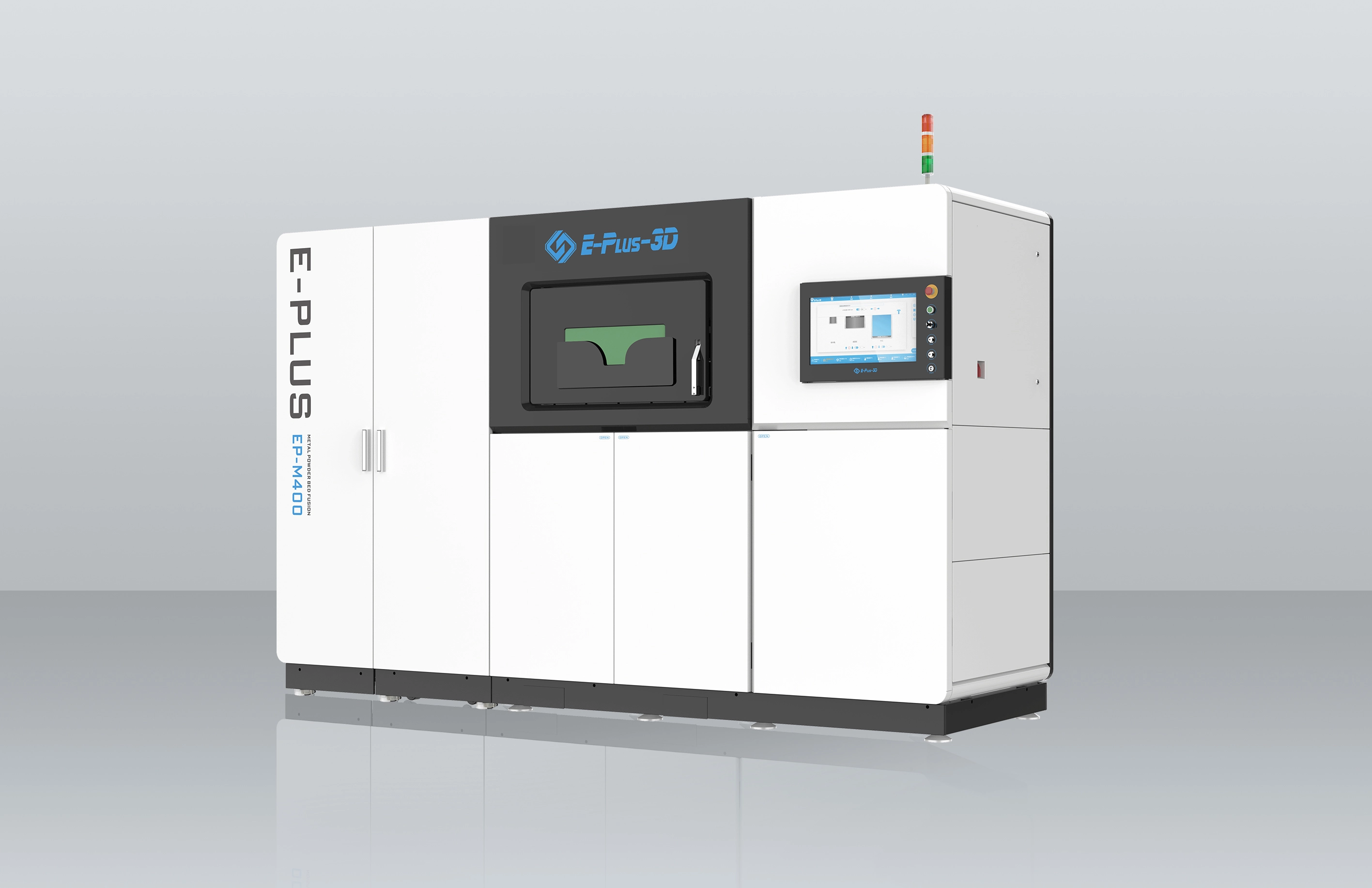

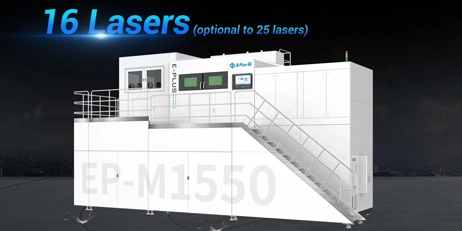

On the other hand, this list fully demonstrates the recognition on Eplus3D metal additive manufacturing capacity from official authority and shows that Eplus3D metal AM machines are recognized by high-precision industries such as aerospace. Eplus3D has developed multiple large format metal PBF machines, among which EP-M1550 , with build volume of 1550 x 1550 x 1100 mm, is an ideal choice for direct manufacturing of large-size, high-precision and high-performance parts for aerospace & aviation and other industries. It uses a large building envelope and 16-laser system to ensure a high efficiency production. The multi-laser precise positioning and overlapping control technology offers uniformity and stability throughout the whole printing phase.

Generally speaking, metal 3D printing technology is crucial to the future development of the aerospace field, which will drive the entire industry towards more efficient, lighter, safer and more sustainable direction. As industry-leading metal 3D printing solution provider, Eplus3D will continue to provide more customized metal additive manufacturing solutions to aerospace and other customers through continuous innovation and improvement.

About MIIT

MIIT, the Ministry of Industry and Information Technology, is the sixth-ranked executive department of the State Council of the People's Republic of China. It is responsible for regulation and development of the postal service, Internet, wireless, broadcasting, communications, production of electronic and information goods, software industry and the promotion of the national knowledge economy.