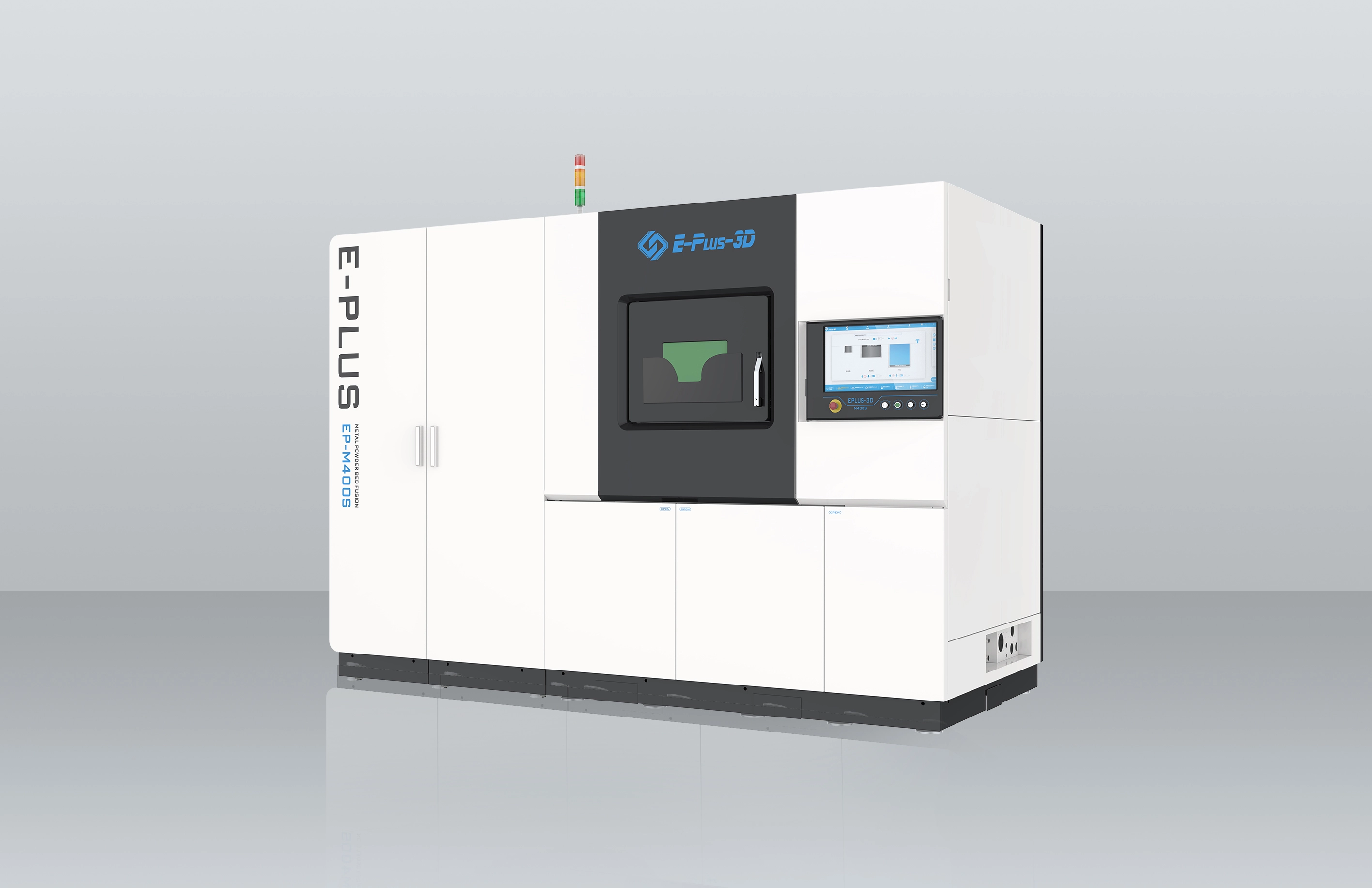

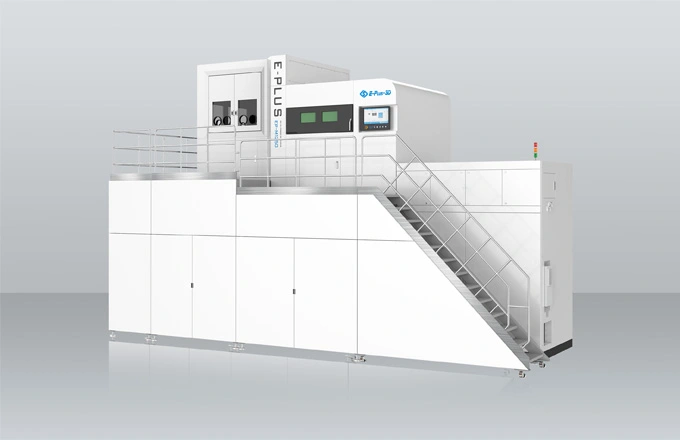

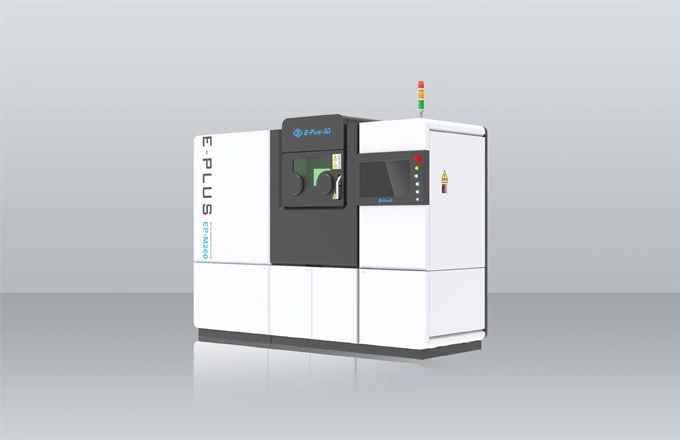

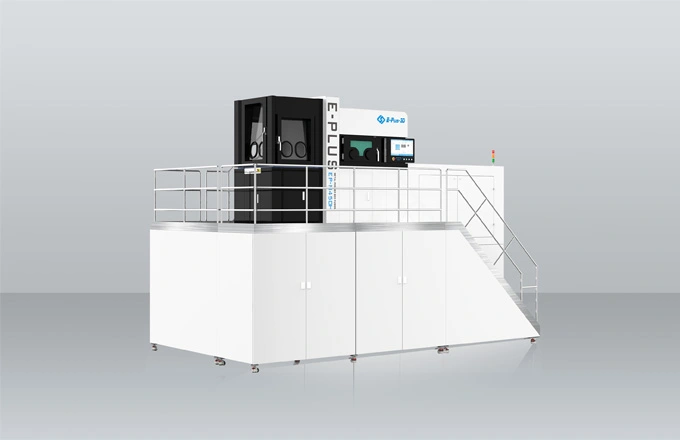

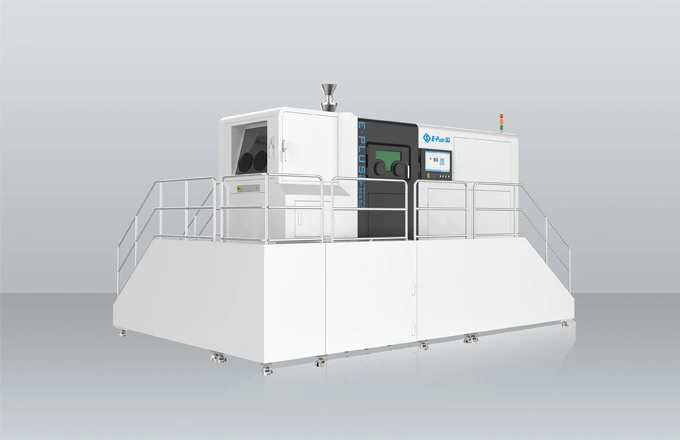

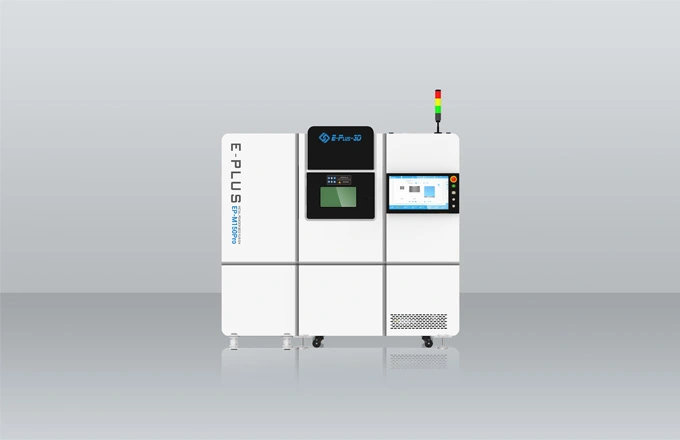

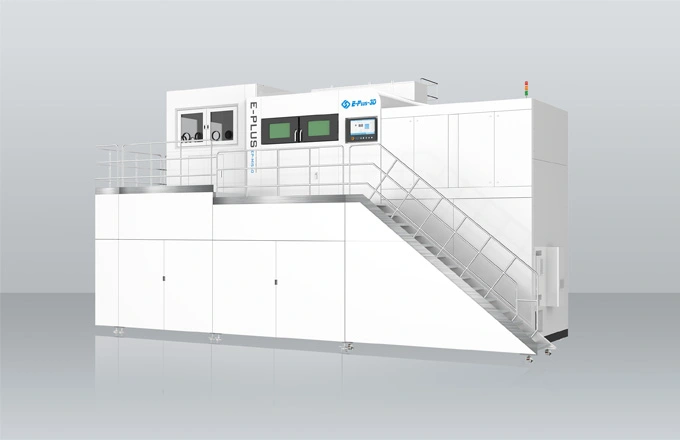

In recent years, the aerospace industry has seen a significant transformation with the introduction of large format metal 3D printers. These innovative machines are revolutionizing the way components and parts are manufactured for aircraft and spacecraft, offering more efficient production processes and greater design flexibility. In this blog, we will explore the impact of large format metal 3D printers in the aerospace sector and how they are shaping the future of aircraft manufacturing.

Advantages of Large Format Metal 3D Printers in Aerospace

One of the key advantages of large format metal 3D printers in aerospace is the ability to create complex geometries that were previously impossible with traditional manufacturing methods. This allows designers and engineers to optimize the performance of components, reduce weight, and improve fuel efficiency. Additionally, large format metal 3D printers can produce parts with superior strength and durability, making them ideal for critical applications in the aerospace industry.

Another major benefit of large format metal 3D printers is the reduction in lead times and production costs. By eliminating the need for tooling and reducing material waste, these machines can produce parts faster and more cost-effectively than conventional methods. This not only speeds up the development process but also improves overall efficiency and productivity in aircraft manufacturing.

Furthermore, large format metal 3D printers enable the production of customized and low-volume parts on-demand, which is particularly valuable in the aerospace industry where every component is precision-engineered and tailored to specific requirements. This flexibility allows manufacturers to quickly respond to design changes, test prototypes, and iterate on new concepts without the time and expense of traditional production processes.

Applications of Large Format Metal 3D Printers in Aerospace

Large format metal 3D printers are used in a wide range of applications in the aerospace industry, from complex engine components to lightweight structural parts. These machines can produce intricate internal features, intricate cooling channels, and even parts with integrated sensors, reducing the need for assembly and improving overall performance.

Additionally, large format metal 3D printers are used to create advanced materials such as titanium, aluminum, and nickel alloys, which are essential for aerospace applications. These materials offer superior strength-to-weight ratios, corrosion resistance, and high-temperature properties, making them ideal for use in aircraft engines, landing gear, and other critical components.

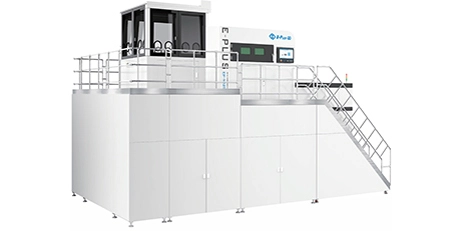

Overall, the impact of large format metal 3D printers in aerospace is transforming the way aircraft and spacecraft are designed, manufactured, and operated. These innovative machines are driving greater efficiency, flexibility, and performance in the aerospace industry, making them a key technology for the future of aircraft manufacturing.

In conclusion, large format metal 3D printers are revolutionizing the aerospace industry by offering new capabilities and advantages that were previously unattainable with traditional manufacturing methods. From complex geometries to improved material properties, these machines are shaping the future of aircraft design and production. As the technology continues to advance, we can expect to see even greater innovations and advancements in aerospace manufacturing with the help of large format metal 3D printers.