Metal powder is a very important consumable in 3D printing. The 3D printing metal powder generally requires high purity, good sphericity, narrow particle size distribution, and low oxygen content. At present, the metal 3D printing materials used in 3D printing mainly include titanium alloy, cobalt-chromium alloy, stainless steel and aluminum alloy, etc. As the most important link in the 3D printing industry chain of metal parts, 3D printing metal powder is also the greatest value.

The shape of 3D printing metal powder

In the manufacturing process of 3D printed metal powder, different shapes of particles, such as a spherical, oval, porous sponge, tree, and other types, will be produced due to different requirements and different manufacturing methods. Different shapes of 3D printing metal powder mean different fluidity and looseness, which will have different effects on the printing of products.

Generally, spherical or elliptical powder has good fluidity, so the powder supply system of the 3D printer will not be blocked due to poor circulation during printing. But also can be conveniently laid into a thin layer. Let the 3D printed objects have higher accuracy, and all parts will be more uniform. For the current technology, the spherical powder is undoubtedly a better choice. However, because of the large gap, the quality of the products printed with spherical powder is not as good as that of other shapes. If you want better quality, you need to make the diameter of the powder smaller.

Size of 3D printing metal powder

Usually, it is better to make the diameter of 3D printed metal powder smaller. This is because the smaller the diameter of the powder, the better the sintering, and the higher the driving force for sintering. Not only does the smaller the diameter, the smaller the gap will be when stacking so that the quality and strength of the product will be guaranteed. However, the diameter of the 3D printing metal powder is not as small as possible, because if the diameter of the powder is too small, it may cause the phenomenon of spheroidization during sintering, which will lead to uneven powder spreading, thus affecting the printing accuracy.

Purity of 3D printing metal powder

In addition, the oxygen and nitrogen contents also need to be strictly controlled. At present, the powder preparation technology for metal 3D printing is mainly based on atomization. The powder has a large specific surface area and is easy to oxidize. In special application fields such as aerospace, customers have stricter requirements on this index, such as the oxygen content of superalloy powder is 0.006%-0.018%, titanium alloy powder is 0.007%-0.013%, and stainless steel powder is 0.010%-0.025%.

Particle size distribution of 3D printing metal powder

The choice of particle size of metal powder for 3D printing is mainly divided according to metal printers with different energy sources. The printer with laser as an energy source is suitable for using 15-53μm powder as consumables because of its fine focusing spot and easy melting of fine powder. The powder supply method is layer by layer. The powder-spreading printer with an electron beam as an energy source has a slightly thicker focusing spot, which is more suitable for melting coarse powder, especially for coarse powder of 53-105μm; For coaxial powder feeding printer, powder with a particle size of 105-150μm can be used as consumables.

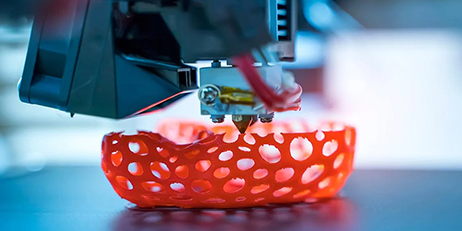

As a prominent player among industrial 3D printer manufacturers based in China, Eplus3D offers a remarkable selection of high-caliber industrial 3D metal printers for sale. These cutting-edge machines are meticulously crafted to accommodate a diverse range of 3D printing metal powders, showcasing Eplus3D's dedication to delivering top-notch quality and performance. If you have any questions about our 3D metal printing machines and 3D printing metal powders, don't hesitate to contact us directly.

How metal powder is made for additive manufacturing?

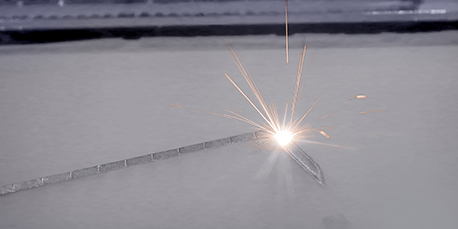

Creating metal powder for additive manufacturing involves several intricate steps, akin to a delicate alchemy. First, the chosen metal undergoes a transformation akin to turning butter into liquid gold, albeit at significantly higher temperatures. This process, known as heating, melts the metal to a molten state, rendering it malleable for the next stage.

Following this, the molten metal is subjected to intense pressure as it is forced through a narrow opening, reminiscent of squeezing toothpaste through a tiny nozzle. This action, termed as breaking up, fragments the molten stream into fine droplets, resembling a metallic rainfall.

The next phase is crucial: the droplets encounter a high-pressure stream, typically of gas or water, which further fragments them into minuscule particles. This powderful transformation ensures the creation of uniformly sized particles, essential for precise additive manufacturing processes.

Finally, as the droplets disperse, they rapidly cool and solidify, akin to a solidification station. This rapid cooling process solidifies the molten metal into individual powder particles, each poised to contribute to the intricate layers of additive manufacturing, where innovation and precision converge to shape the future of metal fabrication.

Types of 3d printing metal powder atomization for additive manufacturing

In Eplus 3D printing metal powder production, two primary atomization methods prevail:

Gas Atomization: Widely adopted, this method employs inert gases such as argon to fragment the metal. It yields highly spherical particles, a trait favored in numerous additive manufacturing techniques due to their flowability and uniformity.

Water Atomization: In contrast, water atomization utilizes a high-pressure water jet to break down the metal. Although resulting particles may be less spherical, this technique can offer a cost-effective alternative for certain applications where precise shape isn't paramount, making it an attractive option in specific scenarios within additive manufacturing.

What metal powder is used in 3D printing?

A wide variety of metal powders are used in 3D printing, catering to different needs in terms of strength, weight, corrosion resistance, and other properties. Here are some of the most common ones:

aluminum powder for additive manufacturing

Stainless Steels (like 17-4 PH, 316L, 304): Popular for their versatility, offering a good balance of strength, corrosion resistance, and affordability.

Tool Steels (like H13, A2, D2): Known for their exceptional hardness and wear resistance, used for tools and molds.

Specialty Alloys (like Inconel, Cobalt Chrome): Cobalt chrome powder, offer unique properties like high-temperature resistance or biocompatibility, used in demanding applications like aerospace or medical implants.

Titanium (like Ti64): Valued for titanium 3d printing powder, high strength-to-weight ratio and excellent corrosion resistance, used in aircraft parts and medical devices.

Aluminum (like 4047, 6061, 7075): A lightweight option with good strength, aluminum powder for additive manufacturing, commonly used for prototypes and functional parts.

This is not an exhaustive list, and other metal powders like copper-based alloys or nickel-based alloys, nickel alloys metal powder can also be used depending on the specific application.