Polymer is the most commonly used 3D printing material due to the relatively low cost of prototyping and production compared to other heat resistant 3D printing materials.

- PA12 Powder

PA12 is made from fine polyamide powder. Compared to traditional 3D printed plastic material,

PA12 is waterproof and has excellent resistance to chemicals such as alcohol, fuels, detergents

and oil. Most importantly, it is very suitable for high temperature use.

PA12 has a melting point of about 180°C, which can be safely used below 95°C.

-Aluminum-filled Nylon Powder

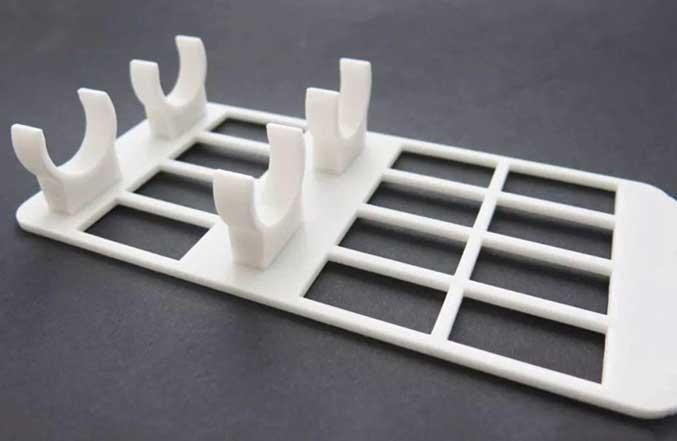

Aluminum-filled nylon powder is a mixture of nylon powder and aluminum powder, printed by

SLS technology. Because it is reinforced nylon, it has excellent durability and physical properties.

The melting point of aluminum powder composite nylon is 172-180°C and the softening

temperature is 169 °C, so it is the best choice for parts which need good mechanical properties

and high temperature resistance.

-Glass Filled Nylon Powder

Glass-filled nylon powder is a mixture of nylon powder and glass beads, which is more durable

than standard nylon powder. The material has good wear resistance, high strength, melting

point of 176°C, and can be used in high temperature or under the conditions that a particularly

high thermal deformation temperature is required.

Based on the characteristics of good heat resistance, dimensional stability and thermal aging stability, glass-filled nylon parts can be directly used in automobile, electric tools and prototype industries.

Eplus3D SLS polymer 3D printers EP-P3850 and EP-P420 are flexible machines heat-resistant polymer 3d printing. We also provide advanced processes for industrial SLS heat resistant 3D printing with the most various polymer materials optional, including polymer material PA12, PA12GF, PA11, PA11CF, etc. with high performance of mechanical properties for functional test and end products. Welcome to discuss with us for more details.