AM Futures, a leading UK additive manufacturing (AM) equipment provider, has been named the agent for Eplus3D machines in the UK, following Eplus3D's successful installation of over 100 metal PBF machines in Europe. This partnership aims to expand into the UK market by offering customized metal AM solutions that provide consistent part quality, maximizing uptime and delivering the optimal return on investment (ROI) for customers.

Ludwigsburg, Germany - February 2025 - AM Futures, the UK’s leading additive manufacturing (AM) equipment provider, has partnered with Eplus3D to expand the company’s industrial AM footprint to the UK market, offering scalable metal AM systems tailored to customer requirements.

The new collaboration will provide companies from across the advanced manufacturing sector with access to the latest generation of AM technologies. The team at AM Futures will work closely with customers to develop the exact Eplus3D system specification that suits their unique needs.

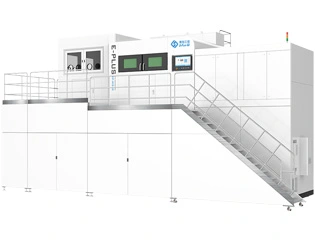

Figure 1: Fostering AM market development in the UK: AM Futures and Eplus3D

Eplus3D offers scalable, industrial-grade Metal Powder Bed Fusion (MPBF) technologies with a range of build volume from 260 x 260 x 390 mm to 2050 x 2050 x 1100 mm (with a customizable Z-axis up to 2000 mm), as well as configurations varying from single laser to 64 lasers. Eplus3D Metal PBF machines are compatible with a wide array of metal materials, including aluminium alloys, titanium alloys, cobalt chrome, nickel-based alloys, stainless steels, tool steels, copper alloys, and other micro-grade metals.

All Eplus3D systems have been engineered with a focus on ensuring consistent part quality, maximizing uptime and delivering the optimal return on investment (ROI). Notably, over 100 Eplus3D Metal PBF systems are already operational in Europe, and an expansion into the UK is imminent.

Nigel Robinson, Founder and Director at AM Futures, commented: “We are thrilled to work alongside the team at Eplus3D to bring their high-performance metal PBF machines to the UK market. I have been impressed at the way the Eplus3D team helps to enable customers with their technology. When it comes to AM, quality and reliability should be a given. As the industry has expanded and technology evolved, we see more customers seeking greater value in the supply chain to achieve the best possible ‘piece part price’. Eplus3D is now offering the step change required.”

Martin Bizot, Account Manager at Eplus3D Tech GmbH, commented: “The UK is a highly advanced market in metal additive manufacturing, and with AM Futures’ expertise in metal AM, combined with the productivity and technical advantages of our machines, we are ready to unlock new opportunities and push the boundaries of metal AM production.”

This partnership marks a significant milestone for both AM Futures and Eplus3D, as we strive to innovate and advance the additive manufacturing industry together. With Eplus3D's cutting-edge technology and AM Futures' expertise in the UK market, we are poised to make a lasting impact on the manufacturing landscape.

For more information on AM Futures, please visit: https://am-futures.com/

For more information on Eplus3D, please visit: https://www.eplus3d.com/

About AM Futures

At AM Futures, we specialise in bringing advanced AM Manufacturing technologies and manufacturing capability to businesses across diverse industries.

As an authorized reseller and agent for renowned brands like 3ntr, Caracol TOP Additive, we offer premium industrial-grade 3D printing machines designed to meet the most demanding production needs. Our mission is to empower organisations to harness the transformative potential of additive manufacturing, helping them innovate, streamline processes, and achieve remarkable results.

AM Futures is committed to more than just supplying cutting-edge technology; we provide a complete support ecosystem to ensure our clients have the guidance, training, and expertise they need to make the most of their 3D printing investment.

https://am-futures.com/

About Eplus3D

Since founding the first PBF machine in China in 1993, Eplus3D has emerged as a prominent leader in providing comprehensive solutions for metal additive manufacturing. Our track record showcases our ability to assist customers across more than 40 countries worldwide, enabling them to enhance their component manufacturing through the implementation of end-to-end process chains. With an extensive presence of over 100 systems in Europe, specifically in the aerospace, medical, and mechanical engineering sectors, we, as 3D printer developers, possess profound expertise within these industries.

Situated in Ludwigsburg near Stuttgart, Germany, our team of engineers excels in providing proficient guidance and support to our esteemed clientele. We are well-equipped to cater to customers in German, English, Spanish, French, and Arabic languages. Our commitment lies in helping our customers achieve rapid success and sustainable growth in metal 3D printing. To facilitate this, our innovation center houses multiple machines in Ludwigsburg, alongside a warehouse stocked with essential consumables and spare parts.

In the field of large LPBF plants, our company can prove its global market leadership. Since spring 2024, our customer, a service provider from Austria, has been economically processing metal powder into components up to 650 x 650 x 800 mm in size with the largest metal 3D printer in Europe. At about the same time, we presented the world's largest powder bed system, the EP-M2050 with a capacity of 4 m³ and up to 64 lasers.

https://www.eplus3d.com/