Reduced Mold Turnaround Time: Traditional moldmaking generally involves the use of molds made by skilled tool and moldmakers. This process can take a long time, often weeks or even months. Additive manufacturing allows for rapid prototyping and tooling production, significantly reducing lead times.

Reduced Manufacturing Costs: Traditional mold making can be expensive due to the need for skilled labor and specialized machinery. Additive manufacturing reduces the cost of producing molds by eliminating the need for specialized tooling and reducing the labor required for mold making.

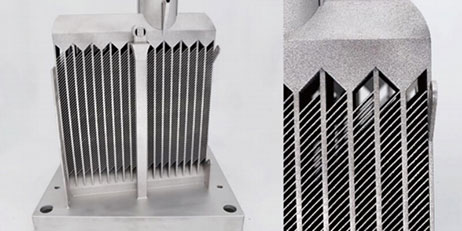

Increased Design Flexibility: Additive manufacturing allows the production of complex geometries that were previously difficult or impossible to produce with traditional tooling techniques. This provides designers with greater design flexibility, allowing them to create more complex and intricate parts.

Increased Customization Capabilities: Additive manufacturing can also produce custom molds to meet specific needs. This is especially useful where unique parts need to be produced in small batches.

Improved Mold Performance: Additive manufacturing can produce molds with improved performance characteristics, such as increased durability and better cooling channels. This can lead to the production of higher quality parts with less metal scrap and the possibility of rework.

Overall, additive manufacturing has the potential to revolutionize the tooling industry, offering faster turnaround times, lower costs, greater design flexibility, and improved performance. While additive manufacturing empowers the mold industry, Eplus3D has also been committed to providing complete and efficient additive manufacturing solutions for customers in the mold industry.