Selective laser sintering (SLS) 3D printing is a favored additive manufacturing (AM) technology by engineers and manufacturers from different industries. In this article, we will introduce the process, applications and scenarios why SLS 3D printing is different from other additive manufacturing and traditional manufacturing methods.

-3d-printing.jpg)

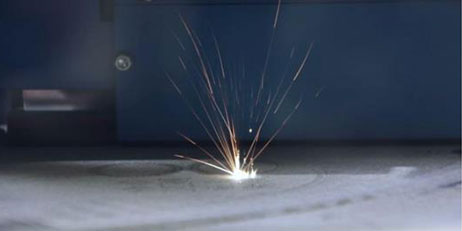

Selective laser sintering is an additive manufacturing (AM) technology which applies a high-power carbon dioxide laser to sinter polymer powder to form the product based on a 3D model. In recent decades, it has been a popular choice for engineers and manufacturers. However, its features of complexity, high requirements and high prices have restricted its application in large-scale company and manufacturers.

With the development of machinery, materials, software and equipment technology, it has been more suitable for large-scale applications from rapid prototyping to customized manufacturing, and enabled more and more companies to use this technology in high-tech industries. Since the unmelted powder supports the part during the printing process, there is no special support required. It makes SLS 3D printing quit suitable for complex geometries.

Parts printed by SLS 3D printing have excellent mechanical properties with higher strength than traditional manufactured products .The most common material for selective laser sintering is nylon, a high-performance engineering thermoplastic used for functional prototyping and end-use production. Nylon is an ideal choice for complex components and durable parts with high consistency.

SLS 3D printed nylon parts are strong, hard and durable. The finished product has good durability and good abrasion. Nylon is resistant to ultraviolet light, heat, moisture, solvents, temperature and water. Other technologies (SLA or FDM) are usually too brittle and flexible, and not detailed enough. SLS 3D printed nylon parts are not allergenic, which means they can be worn at any time and can be used safely in many situations.

SLS printing is a high speed additive manufacturing technology . Compared with the methods used in other processes such as industrial FDM, it has a faster scanning speed and more accurate. It is also an advanced technology for a wide range of applications. Whether it is suitable for you depends on your part design, material requirements and the application. So please choose SLS 3D printing according to your own actual needs.

-3d-printing-1.png)

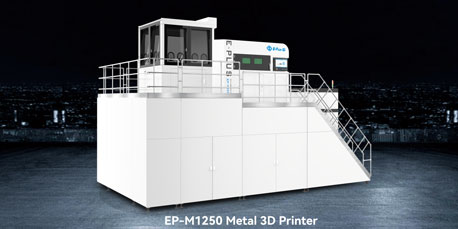

About Eplus3D SLS 3D Printer

As an expert in 3d printing technology, Eplus3D has high-quality SLS 3D printers for sale. Eplus3D SLS polymer 3D printers are flexible machines for industrial grade production and research. We also provide advanced processes for industrial SLS 3D printing with the most various polymer materials optional, including polymer material PA12, PA12GF, PA11, PA11CF, TPU etc. with high performance of mechanical properties for functional test and end products.

Eplus3D EP-P420 adopts polymer powder bed fusion (PPBF™) technology, with max up to 420x420x465mm building cylinder, ensures you the capability to print medium & large size parts for customized products and small batch production. Thanks to its innovative software and hardware, the EP-P420 is well designed user-friendly and cost-effective.

-3d-printing.jpg)

-3d-printing-1.png)