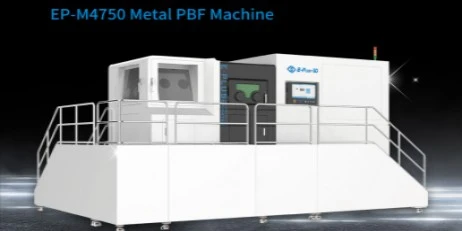

Ⅰ. Technical principle of selective laser sintering

The technology uses powder laying to lay a layer of powder material flat on the surface of the molded part and heats it to a temperature just below the sintering point of the powder. The control system controls the laser beam to scan over the powder layer according to the cross-sectional contour of the layer so that the temperature of the powder rises to the melting point, sintering and bonding with the molded part below. After the completion of one layer, the table drops a layer of thickness and the spreading roller spreads a layer of uniform and dense powder on it to carry out the sintering of a new layer of cross-section until the whole model is completed.

Ⅱ. Selective laser sintering process characteristics

(1) Selective laser sintering technology can be made into a mold of parts with arbitrarily complex geometry, without the restriction that the tool cannot reach certain surfaces in the traditional mechanical processing method.

(2) The manufacturing process does not need to design the mold, nor does it need the traditional tooling or tooling and other production preparation work, the processing process only needs to be completed on a single piece of equipment, and the molding speed is fast. Used for mold manufacturing, can greatly shorten the product development cycle, reduce costs, generally only 30%-50% of the traditional processing methods of man-hours and 20% to 35% of the cost.

(3) The integration of design and manufacturing is realized; the transformation of CAD data (layering and level information processing) can be completed 100% automatically, and the CNC code can be generated automatically according to the level information to drive the molding machine to complete the layer-by-layer processing and stacking of materials.

(4) Selective laser sintering is non-contact processing, and there is no vibration, noise and cutting waste during the processing.

(5) The material utilization rate is high, and the un-sintered powder can be used to support the next layer of sintering, so the SLS process does not require the design and fabrication of complex support systems.

(6) The most significant feature of selective laser sintering is the diversity of forming materials. Theoretically, any powder material that can form atomic linkage between powders after laser heating can be used as SLS forming materials. At present, the commercialized materials mainly include plastic powder, wax powder, laminated metal powder, ceramic powder with binder coated on the surface, laminated sand, etc.

Ⅲ. Selective laser sintering materials

Selective laser sintering process materials are widely adaptable, not only to manufacture plastic parts, but also ceramic, paraffin and other material parts. In particular, it is possible to directly manufacture metal parts, which makes the SLS process quite attractive.

The materials used for the SLS process are various types of powders, including metal, ceramic, paraffin, and polymer powders, with powder sizes generally ranging from 50 to 125 microns. Indirect SLS composite powder usually has two types of mixing type: one is the binder powder and metal or ceramic powder in a certain proportion of mechanical mixing; the other is the metal or ceramic powder into the binder dilution solution, the production of metal or ceramic powder with binder package. Experiments show that the latter preparation, although complex, but the sintering effect is better than the former.