Metal 3D printing technology mainly includes "powder bed laser selective melting" and powder/wire feeding deposition. Among them, the "powder bed laser selective melting" technology is suitable for the manufacture of small and complex components, while the "melting deposition" technology is suitable for the manufacture of large key load-bearing components for major equipment with higher technical difficulty.

In order to achieve better results for 3D printing parts, it is critical to accelerate the development and upgrade of materials supporting 3D printing technology. In-depth research on the basic issues of the preparation and forming of meta-materials such as molten pool metallurgy, solidification, thermophysics, solid phase transition, etc. in the melting deposition printing process is of great significance to promote the 3D printing technology.

Generally speaking, the metal powders used in metal 3D printers include tool steel, stainless steel, martensitic steel, pure titanium and titanium alloys, aluminum alloys, nickel-based alloys, copper-based alloys, cobalt-chromium alloys, etc. In this article, you will learn more about subdivided material.

3D printing powders-Titanium

Titanium is a strong, lightweight, heat-resistant and chemical-resistant metal. Generally speaking, titanium is very challenging in processing, resulting in its high cost. The common 3D printed titanium is Titanium 64 (Ti-6Al-4V), which can be used for parts processing with very high strength and weight ratio, such as applications in the aerospace field.

3D printing powders-Nickel

Nickel plays a key role in the electronic functions of mobile phone batteries and devices. It is the main component of the electronic circuit component of the mobile phone-the capacitor. It is reported that the new generation of capacitors abandon the expensive old technology. It no longer uses precious metals such as gold and palladium, but uses multi-layer ultrafine nickel powder, which reduces the construction cost of components. The shape memory, electrochemical and magnetic properties of nickel can directly promote the development of science and technology. In innovative applications, the characteristics of nickel alloys also make it compatible with other elements and materials.

3D printing powders-Stainless steel

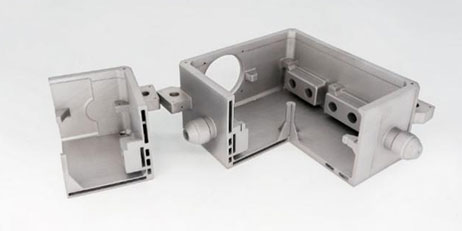

Stainless steel is characterized by high mechanical strength and strong corrosion resistance. From the early industrial manufacturing to the application of 3D printing technology, the metal material is widely used in the production of various industries. 3D printing stainless steel materials mainly include heat-treatable 17-4 PH stainless steel and extremely corrosion-resistant 316L stainless steel. Among them, tool steel is used in various manufacturing tools. Any item on the cutting, stamping, molding or forming line may be made of tool steel.

3D printing powders-Aluminum

Currently, aluminum alloys used in metal 3D printing mainly include AlSi12 and AlSi10Mg. Al-Si 12 is a lightweight additive-manufactured metal powder with good thermal properties and can be used in thin-walled parts. For example, heat exchangers or other auto parts can also be used in aviation industry-level prototypes and parts manufacturing.

3D printing powders-Refractory metal

There are relatively few types of refractory metals, including tungsten, rhenium, niobium, molybdenum, and tantalum. All of them are known for their high heat resistance, with melting points generally exceeding 2000°C, inactive chemical reactions, high density, and high hardness. Among them, tantalum has high corrosion resistance and very good conductivity, which has broad application prospects in the electronics industry. According to the Los Alamos National Laboratory, 60% of this material is used for vacuum furnace parts and electrolytic capacitors. In theory, tantalum can increase the radioactivity of nuclear particles.

Conclusion:

The application fields of metal 3D printing materials are quite extensive, including aerospace, automobile manufacturing, injection molds, food processing, medical and health, electric power, light metal alloy casting and other fields. Of course, the classification of 3D printing metal materials is not limited to these, while there are other printing materials such as rock, cement, paper and so on. With the continuous development of 3D printing materials, processes, and equipment, 3D printing technology will effectively support our country's steady progress toward a manufacturing power.