Since founding the first PBF machine in China in 1993, Eplus3D is engaged in research and development of industrial-grade Additive Manufacturing systems and application technologies using with MPBF™ (Metal Powder Bed Fusion) and PPBF™ (Polymer Powder Bed Fusion) 3D printing technology. Eplus3D provides professional application solutions for the fields of aerospace & aviation, energy, oil & gas, automotive, tooling, healthcare, consumer goods and precision manufacturing.

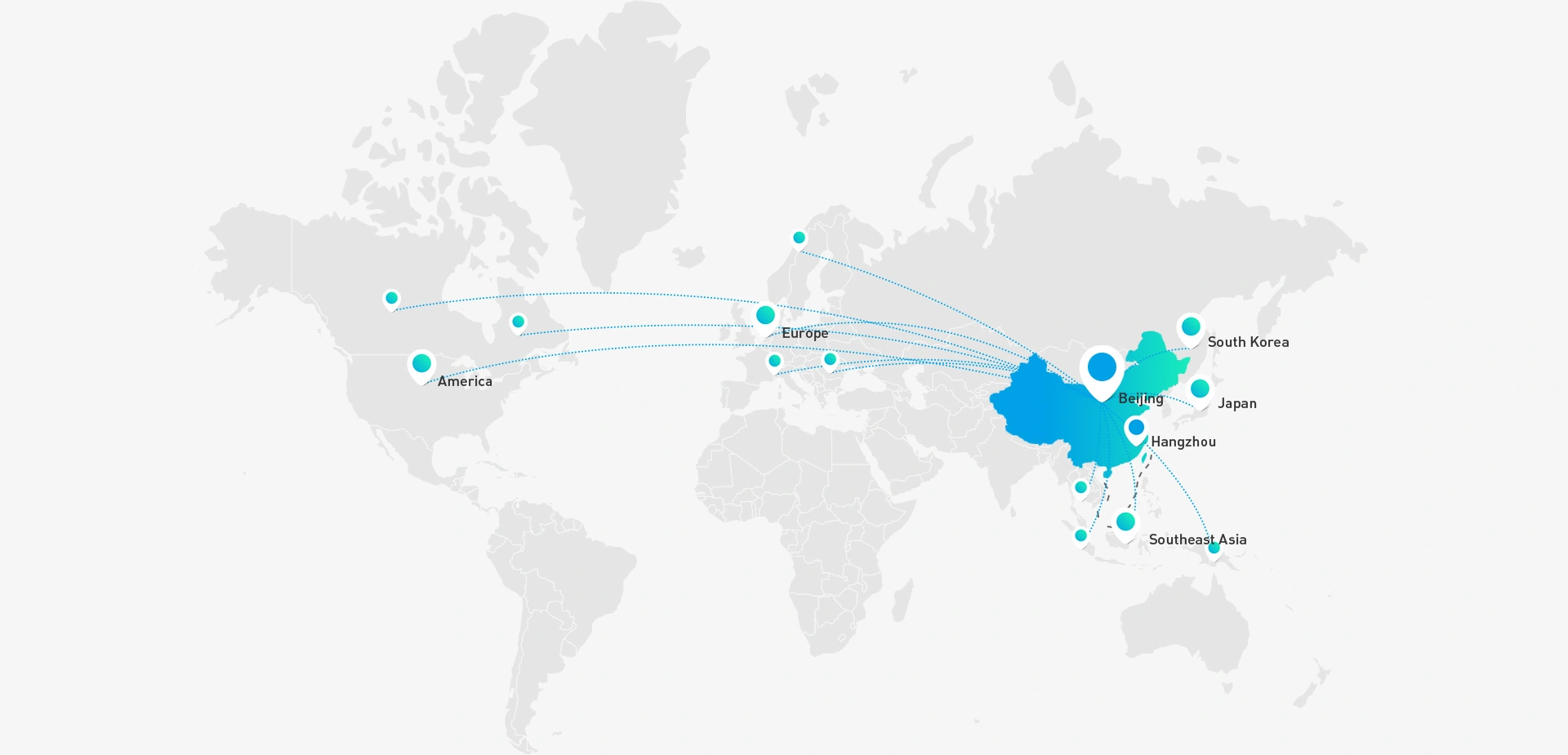

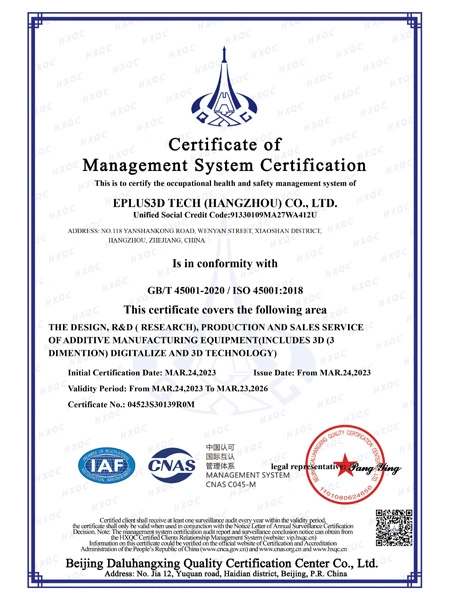

Eplus3D has four facilities in Beijing, Hangzhou, Stuttgart and Houston, with an annual scientific research investment of more than 20% of the revenue with comprehensive invention patents, utility model patents, software copyrights as well as appearance patents. It has made great achievements in the design, process, software, materials and post-processing development for additive manufacturing and has successfully implemented AM solutions at customer site in more than 40 countries and regions such as Europe, Americas, Middle East, East Asia and Southeast Asia.