Acetabular cup is a representative application of 3d printing in the medical field, and it is also one of the only three products in China that have obtained the registration certificate for orthopedic implants and medical devices with 3d printing It is very famous and widely known in the 3d printing industry. However, many people are not aware of the traditional manufacturing process of the acetabular cup, the function of each component and how it is installed. In this issue, we use video and animation to understand the traditional and modern methods of acetabular cup processing and explain the structure and biological properties involved.

Traditional machining process of acetabular cup

CNC machining acetabular cup

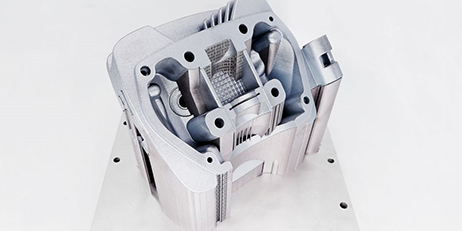

The acetabular cup is composed of a titanium or cobalt-chromium alloy shell and ultrahigh molecular weight polyethylene liner, which requires high precision. The shapes of these components are extremely complex, and custom fixtures are required in traditional machining processes. The wall thickness of the components is very thin, and vibration during machining must be strictly controlled. To process these complex components efficiently and excellently, custom cutters are often required.

The challenge of CNC machining: prolong the life of cutting tool, reduce the vibration during processing, optimize the turning of acetabular cup, control chip flow and maximize turning productivity.

In addition, the machining process is extremely wasteful of materials, and the cost of medical metal materials is also high, which increases the burden on patients.

3d printed acetabular cup

In the manufacturing process of acetabular cups, the biggest difference between 3d printing and traditional CNC machining lies in the advantages of 3d printing in the manufacturing of special lattice structure. In the past, the lattice structure on the surface of the acetabular cup was achieved by coating, which could not guarantee the long-term survival of the prosthesis.

The 3d printing directly creates the lattice structure on the acetabular cup body, simulates the morphology rules of human trabecula, realizes the precise control of pore structure, makes the cup body more functional, effectively promote the growth of bone tissue, and bring better rehabilitation effect.

In the manufacturing process of acetabular cups, mass production can minimize the cost material waste. Personalized manufacturing features can also be tailored to the patient without significantly increasing costs.

Implantation of acetabular cup

Accurate placement of the acetabular cup is critical for the implant to function well to produce a successful clinical result.

Grind the acetabulum and drive it into the cup

The hole in the acetabular cup is used for driving screws to fix the human bone

From a doctor's point of view, metal printing has created a porous implant structure, which can be better integrated into the human body.

Install lining and femoral stem

And while it's not uncommon for people who have traditional implants to have them replaced after 10 to 15 years, 3d printing could extend that to more than 20 years, experts said. The data also emphasize the advantages of 3d printing in the manufacturing of orthopedic implants.

Currently, hundreds of thousands of operations have been performed on 3d printed acetabular cups, and the increase in the numbers and the licensing of medical device registrations represents the improvement of safety and acceptability. Compared with the traditional manufacturing technology, the greater significance of 3d printing in the manufacturing of medical implants lies in its ability to achieve personalized mass production and better medical effects, which is of great significance both for the development of 3d printing in the manufacturing of orthopedic implants and for patients to enjoy better medical results.