ABSTRACT

Building the first titanium bicycle frame in monocoque look with full battery integration worldwide made of 3D printed titanium lugs.

The integration of innovative technologies from Asia to Central Europe, while at the same time maintaining cost efficiency, has been a major challenge in the development process.

After a long history, bicycle manufacturer Möve developed the principle of using Additive Manufacturing (AM) to produce the connectors between the tubes of a bike frame. After evaluating potential partners in order to succeed in this technological breakthrough, Möve identified a need for an excellent collaboration and expertise that would deliver the cost efficiency, design and performance in line with one single manufacturer.

Eplus3D´s team focused on optimizing the cost structure for the production of connectors and ensuring the feasibility of scaling the project into series production. By implementing this approach and supporting Möve in the never made before titanium tubes for the frame, the project was timely accelerated by a minimum of four months, resulting in the creation of a new and distinctive e-bike frame that preserved the original intended monocoque design.

This project illustrates the potential for the bicycle industry through the use of Metal 3D printing and a valuable combination of engineering work from all parties. Recognition of the challenges is critical to mobility industries, prompting them to rethink and redesign how parts´ production are made, delivering a high quality and durable product that enhances the final user experience.

MÖVE INTRODUCTION

Möve, a company with a long-standing presence in Thuringia, Germany, has been combining advanced engineering with outstanding manufacturing quality since 1897. Currently, the manufacturing is based in Katharinenberg, Thuringia. The company prioritizes the “Made in Germany" label, ensuring that its products are manufactured with the highest standards from the very beginning, right through to the finished product. Möve designs, engineers and develops innovative solutions by and for people, to produce the perfect e-bike, adaptative to people´s needs. The recognition of the four-eyes principle ensures the outstanding Möve quality according to the engineering standards.

THE CHALLENGE

Möve recognized the constraints of the industry, such as majority of manual work in conventional frame construction, high tool costs for high standardized bicycles and (e-)bikes frames, incorrect estimated annual bicycle´s frame volume resulting in sales reduction, and composite fiber frames wasted.

The goal of being as cost effective as a bicycle frame made in Asia, with an innovative technology that brings back manufacturing jobs to central Europe, combined with a performance target of a carbon frame, were for sure the major challenges to cope with. During the development phase, the sourcing of oval-shaped, low tolerance titanium tubes seemed to be a major issue, both financially and time-related. In order to receive the hydroformed tubes, the necessary tools would have needed to be developed and produced, which had the possibility of ending the project before it had finally taken off.

THE SOLUTION

After identifying the initial challenges, the first design for additively manufactured connectors between the tubes was created. While reducing the amount of material to a minimum, Möve found Eplus3D to be the best partner, offering the most advanced printing parameters, know-how and design support, resulting in a reasonable price per part. At this point, the Engineer Tobias Spröte saw the full potential and transformative benefits of Metal AM as the next step in building the world's first 3D printed titanium bike frame. As a result, and after combined engineering work from all parties, Möve concluded that Metal Powder Bed Fusion (MPBF™) 3D printing technology, combined with the use of high strength Ti6Al4V material was the only one capable to meet their stated design, performance and cost requirements to produce the lugs for the bicycle.

Eplus3D supported Möve in sourcing high-quality titanium tubes, which were also fully additive manufactured by Eplus3D’s large size Metal printer EP-M650 using Ti6Al4V material. These tubes will in serial production be replaced by hydroformed titanium tubes, but have accelerated the timely realization of the project by 6 months. In addition, very expensive and inflexible tooling costs could be reduced.

Among the many suppliers, Eplus3D stood out for its commitment to going beyond mere production to a thoughtful approach to the challenges that arise in the post-production stage. Möve´s engineering team worked with Eplus3D to develop the innovative solutions, recognizing the need for efficient removal and recycling of the support structure.

In collaboration with Möve, these matters were addressed in order to improve their series production. By focusing on the reduction of support structures, the key parameters were optimized to balance printing speed with desired product properties. This strategic approach not only optimized the post-production process but also aligned with Möve's quality and efficiency goals. Additionally, Möve has created a very thought-through process chain of manufacturing the whole bicycle at their site. This includes the post-processing of additively manufactured components such as surface treatment and machining as well as the assembly of the bicycle using a patented gluing technology. This helps the user to recycle their bicycle and repair it much more economically friendly compared to other bicycles made from carbon fibre.

As explained by Enis Jost, Deputy General Manager of Eplus3D Germany: ”The cost structure is mainly determined by the uptime of the system, the maturity of the processing parameters used and the printing speed associated with these. Since only very few grams of material is used to create the lugs and with the increased system productivity Eplus3D’s machines provide, the raw material cost is of less effect in this case. However, the cost for AM titanium powder is dropping, which helps to create an even better business case. At the same time, Eplus3D’s processes are becoming more and more productive.”

Figure 1 - Capture of the Control Software showing the build job and the printing time for an EP-M400 Quad-laser System

THE RESULTS

The implementation of Metal 3D printing technology, in combination with the 3D engineering expertise, has led to the achievement of remarkable benefits, including cost savings, higher product quality, enhanced efficiency, and sustainability.

COST REDUCTION

This project is particularly beneficial for an economically viable series production, reducing the upfront costs associated with high-volume standardized bicycle and e-bike frames. With higher layer thickness parameter sets and multiple option of machine configuration, Eplus3D provides an optimized solution that can meet the customer needs perfectly and can therefore reduce cost in parts manufacturing, storage and even allow for customized manufacturing of bicycles on demand.

MATERIAL ADVANCEMENTS

By precisely analysing and implementing the correct use of materials such as the titanium alloy (Ti6Al4V), Möve was able to maintain high standards of performance during production, ensuring stability, functionality and durability of the final outcome. The material has the highest performance-ratio and is therefore the best choice for this application type.

INCREASED DESIGN FLEXIBILITY

The use of Metal AM technology together with the engineering expertise of both parties enabled the creation of complex geometries, facilitating the monocoque design of Möve Avian’s e-bike frame. This has been achieved without compromising on the integration of the battery, which remains discreetly hidden inside the down titanium tube, thereby enhancing both the design and functionality of the e-bike. The AM process has also facilitated faster iterative designs build to build, reducing the overall development time and ensuring for the creation of a rider-specific bike when needed.

Figure 2 - Metal 3D Printed Titanium Dropout

These results have been made possible by the currently available and highly productive Ti6Al4V process, which is at least twice as fast as that of our market competitors. Consequently, Eplus3D is able to offer a significantly more attractive cost structure to clients who seek our support in enhancing their prototyping capabilities on one side but even much more while stepping into serial production with this technology.

Figure 3 – 3D-printed Titanium Lugs with hydroformed oval titanium tubes as end pieces result of the bike monocoque design.

Möve Data Sources: Weight (size M) is 1,480 kg.

REMARKABLE MÖVE AVIAN FEATURES RELYING ON METAL 3D PRINTING TECHNOLOGY

MADE IN GERMANY

Every step of production, design and engineering carries the excellence mark “Made in Germany”. The relocation of the supply chain, using the near-shoring principles opens new possibilities for the bicycle industry having a tighter control over their suppliers. Together with the high level of automatization, it enables the manufacturers to produce locally, with a high-volume output and therefore in a cost-effective.

DIFFERENTIATED TITANIUM SURFACE

Relying on abrasive blasting technology, the titanium surface is smoothened resulting in a uniform and matte appearance. Becoming the hallmark of the new Möve Avian.

WEIGHT OPTIMIZATION

Bike weight reduction due to lightweight titanium frames, by reducing support structures after-production. This has been combined with an integrated 250 Wh battery, which has resulted in a weight of 11.8kg.

FLEXFIT TECHNOLOGY APPLICATION

The adhesive chambers for gluing the lugs and tubes and their injection channels were designed and optimized by Möves´ team to achieve a filling of over 98% in the adhesive chambers.

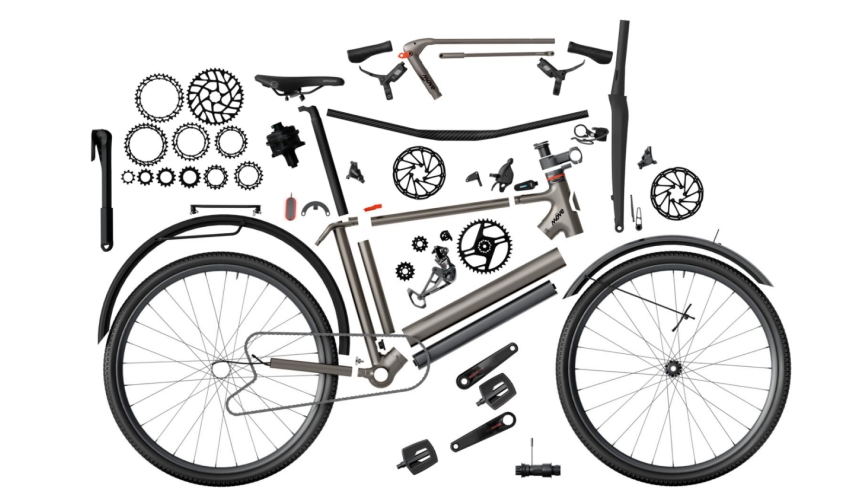

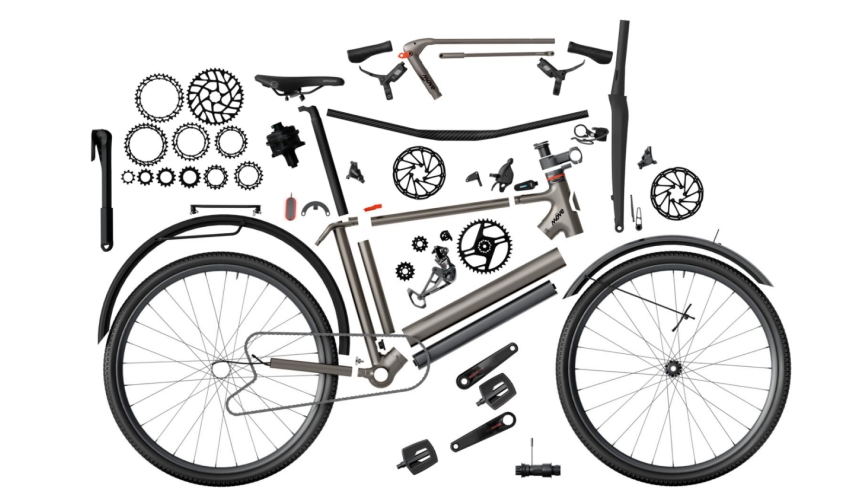

Figure 4 - Components of the Avian

ADDITIVE MANUFACTURING IS THE FUTURE OF THE BICYCLE INDUSTRY

Möve's entry into the field of AM not only represents a significant shift in the way bicycle frames are constructed, but also shows to the remaining industry the potential and high-quality standards achievable with this technology. Möve is setting new standards in the field, paving the way for future innovations and establishing themselves as leaders in this area.

This transformation is clearly visible through the collaborative efforts and expertise contributed by both Möve and Eplus3D. Together, we are pushing the boundaries of what is possible in bicycle frame design and further manufacturing, showcasing a commitment to reshaping the industry landscape. As Enis Jost, Deputy General Manager of Eplus3D Germany, explains: “The potential of AM in the bicycle industry can be fully explored when traditional manufacturers start to design for process and user customization, similar to other emotionally connected devices such as cars and motorcycles. Possible materials include high-performance materials such as Scalmalloy® or Titanium, but also typically casting alloys such as AlSi10Mg or even Stainless Steel.” This process can be particularly beneficial for bicycle components – levers, clamps, shifting equipment, and pedals –, currently typical up to 10.000 parts per year.

To unlock the potential market of MPBF™, “Eplus3D’s engineering team is open to support any mobility company to achieve its performance and cost goals with Metal AM by developing a manufacturing process that also follows the near-shoring principle, supports the great need of personalized products or in-house production”, explains Enis Jost. Furthermore, a standard cost calculation and a basic design review are carried out for each customer. Due to the fully open system architecture, the client can surely develop its own intellectual property (IP) based on the process provided with the machine being installed, therefore further enhancing its expertise in the field and improving the process.

ABOUT EPLUS3D

Since founding the first PBF machine in China in 1993, Eplus3D is engaged in research and development of industrial-grade Additive Manufacturing systems and application technologies using with MPBF™ (Metal Powder Bed Fusion) and PPBF™ (Polymer Powder Bed Fusion) 3D printing technology. Eplus3D provides professional application solutions for the fields of aerospace & aviation, energy, oil & gas, automotive, tooling, healthcare, consumer goods and precision manufacturing.

Eplus3D has four facilities in Beijing, Hangzhou, Stuttgart and Houston, with an annual scientific research investment of more than 20% of the revenue with comprehensive invention patents, utility model patents, software copyrights as well as appearance patents. It has made great achievements in the design, process, software, materials and post-processing development for additive manufacturing and has successfully implemented AM solutions at customer site in more than 40 countries and regions such as Europe, Americas, Middle East, East Asia and Southeast Asia.

APAC Headquarters

Eplus3D Tech Co., Ltd.

Hangzhou, China

P: +86-571-83819589

No. 118 Yanshankong Road, Wenyan, Xiaoshan, Hangzhou, Zhejiang, China, 311258

EMEA Region

Eplus3D Tech GmbH

Ludwigsburg, Germany

P: +49-7141-3888118

Pflugfelder Str. 23, 71636 Ludwigsburg, Germany

Americas Region

EPLUS 3D TECH INC

Houston, USA

P: +1 (281) 302-6160

12425 W Airport Blvd, unit 201, Sugar Land, TX, 77478