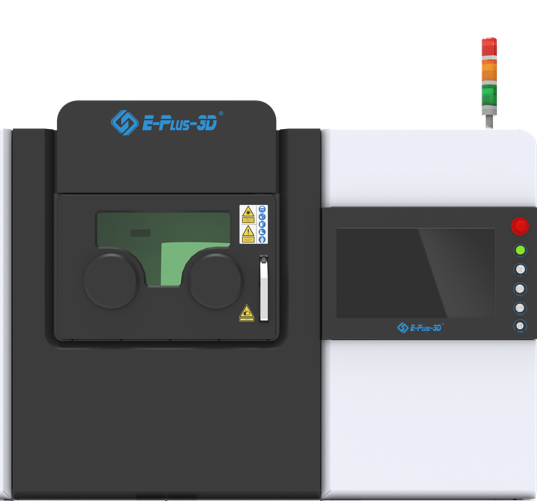

| Machine Model | EP-M300 |

| Build Volume (X x Y x Z) (height incl. build plate) | 300 x 300 x 450 mm (11.81 x 11.81 x 17.72 in) |

| Optical System | Fiber Laser 500 W / 700 W / 1000 W (single or dual-laser optional) |

| Spot Size | 70 - 120 µm |

| Max Scan Speed | 8 m/s |

| Layer Thickness | 20 - 120 µm |

| Theoretical Printspeed | Up to 95 cm3/h |

| Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

| Power Supply | 380 V, 50 / 60 Hz, 5 / 8 kW |

| Gas Supply | Ar / N₂ |

| Oxygen Content | ≤100 ppm |

| Dimension (W x D x H) | 2990 x 1320 x 2590 mm |

| Weight | 2900 kg |

| Software | EPControl, EPHatch |

| Input Data Format | STL or other Convertible File |

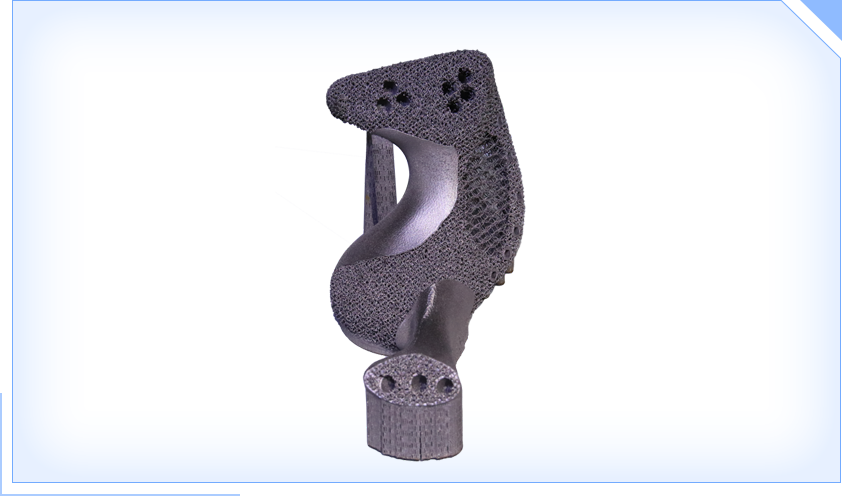

Eplus3D Printer Printing Metal

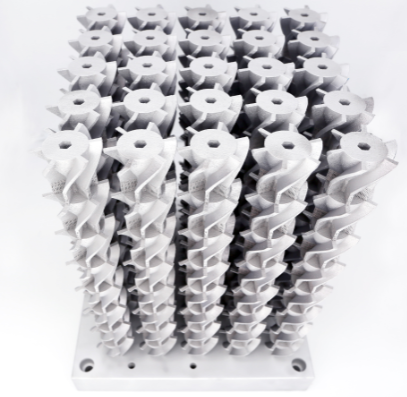

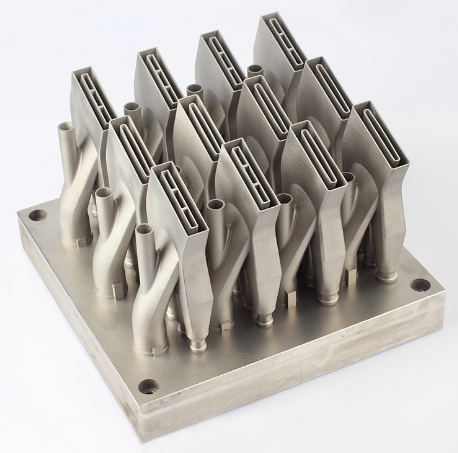

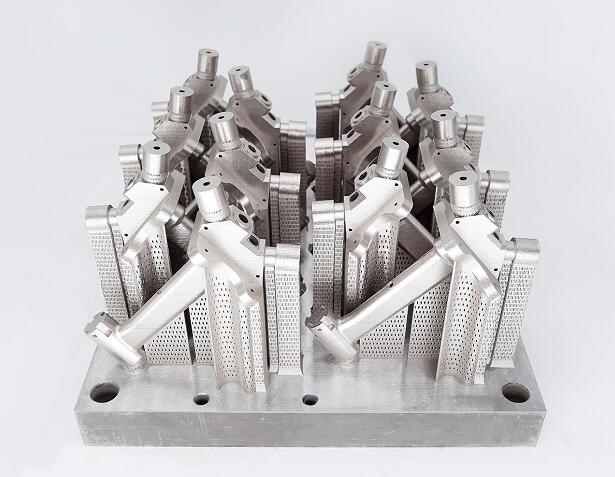

Eplus3D printers are designed to accommodate a range of metal 3D printing materials, including 3d metal printing copper, stainless steel, and aluminum. The copper 3D printing material offers excellent thermal and electrical conductivity, making it well-suited for applications such as heat exchangers, electronics, and intricate artistic designs. Stainless Steel Additive Manufacturing, another popular option, provides superior corrosion resistance and mechanical strength, suitable for a wide array of industrial and consumer products, including automotive parts, medical instruments, and architectural components. Additionally, 3d printing aluminum alloys is recognized for its lightweight properties, making it advantageous for aerospace, automotive, and consumer goods, as well as heat sinks and structural parts. Eplus3D's printers facilitate the precise and efficient use of these materials, enabling the production of high-quality metal parts with diverse characteristics, fulfilling the demands of industries seeking advanced metal 3D printing capabilities.