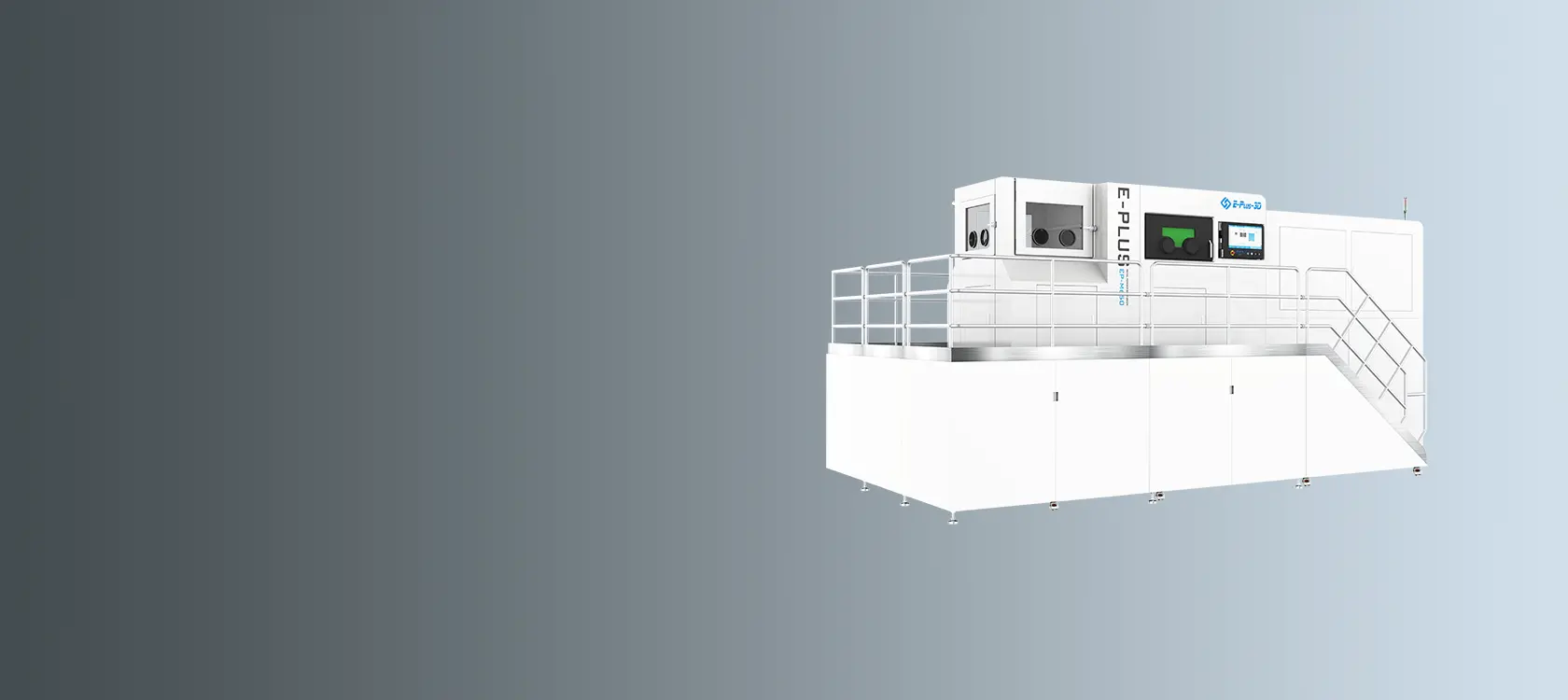

| Machine Model | EP-M650 |

| Build Volume (X x Y x Z) (height incl. build plate) | 650 x 650 x 800 mm (25.59 x 25.59 x 31.49 in) |

| Optical System | Fiber Laser 4 / 6 / 8 x 500 W (700 W and 1000 W are optional) |

| Spot Size | 70 - 120 µm |

| Max Scan Speed | 8 m/s |

| Layer Thickness | 20 - 120 µm |

| Theoretical Printspeed | Up to 320 cm³/h |

| Material | Titanium Alloy, Aluminum Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, etc. |

| Substrate Heating | Substrate Heating Temperature 200 °C |

| Power Supply | 380 V, 50 / 60 Hz, 18 ~ 23 kW |

| Gas Supply | Ar / N₂ |

| Oxygen Content | ≤100 ppm |

| Dimension (W x D x H) | 6800 x 3945 x 3785 mm |

| Weight | 15000 kg |

| Software | EPControl, EPHatch |

| Input Data Format | STL or other Convertible File |

Eplus3D Printer Metal for Additive Metal Printing

Eplus3D printers are designed to work seamlessly with an extensive range of metal powders, including Titanium, Aluminum, Nickel-based alloys, Die Steel, Stainless Steel, and Chrome Cobalt Alloys, cobalt chrome powder, as well as other commonly used materials in metal additive printing. Titanium, known for its exceptional strength-to-weight ratio and biocompatibility, is often utilized in aerospace, medical, and high-performance engineering applications. 3d printing aluminum alloys, prized for its lightweight nature and corrosion resistance, finds widespread use in aerospace, automotive, and consumer goods industries. Nickel-based alloys, including Inconel and Hastelloy, are valued for their high-temperature and corrosion resistance, making them ideal for aerospace, chemical processing, and marine applications. Furthermore, Die Steel, Stainless Steel, and Chrome Cobalt Alloys offer exceptional mechanical properties and wear resistance, catering to a diverse range of industrial requirements. Eplus3D printers' capability to process these varied metal powders ensures versatility and adaptability to meet the demanding needs of modern metal additive printing across multiple industries.