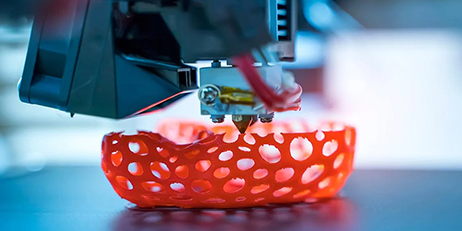

Nylon powder is one of the most important 3d printing materials in the 3d printing market. Nylon is a kind of synthetic polymer, which has high wear resistance, toughness, strength and heat resistance. These properties make nylon an ideal choice for a variety of 3d printing applications.

Main properties of 3d printed nylon materials

a) Mechanical properties. Nylon has good mechanical properties. It has good tensile strength, compressive strength, impact strength, hardness and wear resistance, and is suitable for manufacturing some high-strength and high-toughness products. However, its mechanical properties are greatly influenced by temperature and humidity, and its tensile strength decreases with the increase of temperature and humidity. Nylon has good impact property, which increases with the increase of temperature and water absorption, while hardness decreases with the increase of water content.

b) Electrical properties. Nylon has good electrical insulation performance under low temperature and dry conditions, but its volume resistivity and dielectric strength will decrease, and its dielectric constant and dielectric loss will increase significantly under wet conditions.

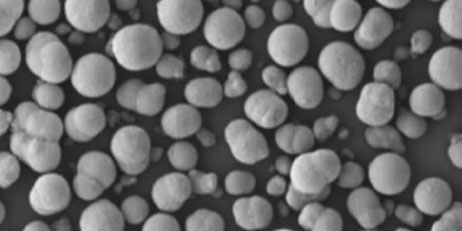

c) Thermal properties. Nylon is a highly polar polymer material, which can form hydrogen bonds between molecules, so it has a high melting point, a narrow melting temperature range and a clear melting point. Compared with other polymer materials, t nylon materials usually have smaller molecular weight, so the heat distortion temperature is lower, generally below 80℃. Since the melting temperature of most nylon is much higher than the thermal deformation temperature, the melting viscosity of nylon is small and cannot meet the requirements of FDM printing. Therefore, most nylon materials are printed by SLS technology.

d) Chemical resistance. Nylon has good chemical stability, crystallization performance and high cohesive energy, and is insoluble in common solvents, because it can resist various chemical substances, including acid, alkali, ketone, alcohol, fat, grease, lubricating oil, gasoline, etc. At room temperature, nylon is dissolved in saturated solutions of some salts and some strong polar solvents. It also shows good stability against certain bacteria, so it can be used to print some biomedical components.

e) Other performance. The weather resistance of nylon is average.. Exposure to the atmosphere for a long time will make it brittle and its mechanical properties will obviously decrease. Adding carbon ash and stabilizer can improve the weather resistance of nylon. At present, several aspects of modification are helpful to provide the comprehensive properties of 3d printed nylon materials, which are reducing water absorption, improving flame retardancy, improving mechanical properties, improving low temperature brittleness and improving wear resistance.

Application of nylon materials in 3d printing

3d printed durable nylon materials are mainly used to make prototypes for functional tests, durable finished parts that do not need to be processed, and precision parts prototypes that meet the needs of manufacturers.

A prominent application of durable nylon material is to make artificial bones for 3d printing. In the field of 3d printing manufacturing of artificial bone abroad, it started earlier in 1990s. Many experts and scholars used alloy materials and thermoplastic polymer materials to study artificial bone, and achieved satisfactory results, which showed that this technology has great potential value and market prospects. Berr and his colleague used a durable nylon material to print the 3d skull data by SLS technology, and obtained a complete skull model. Since then, durable nylon has been used in this field more and more widely. Compared with ABS and other polymer materials, nylon has a slightly higher processing temperature, and its 3d printing products have good flexibility, toughness, high mechanical properties, low shrinkage, strong chemical corrosion resistance and can withstand most organic solvents. The current applications of durable nylon materials in 3D printing mainly include the following aspects:

a) Complex, thin-walled pipes (power tools, aerospace components)

b) Shell products

c) Impeller and connector

d) Consumer goods for sports

e) Dashboard and air outlet

f) Assembly design

g) Functional prototypes

h) Small batch rapid manufacturing

i) Medical applications that require USP Class VI or biocompatibility

Eplus3D SLS polymer 3D printers EP-P3850 and EP-P420 are flexible machines for industrial grade production and research. We also provide advanced processes for industrial SLS 3D printing with the most various polymer materials optional, including polymer material PA12, PA12GF, PA11, PA11CF, etc. with high performance of mechanical properties for functional test and end products. Welcome to discuss with us for more details.