3D printing, also called “additive manufacturing (AM)” or “rapid prototyping (RP)”, is a process of using computer-aided designs or manufacturing technology to make three-dimensional products from digital models. 3D printing technology has been applied to various industries, such as tooling, automotive, aerospace consumer products and others. But it’s still relatively new to dentistry. Today we will present you the major advantages and challenges of 3D printing in dentistry compared to traditional technology to help you better understand their differences.

Advantages:

1. Allowing for Customization

Customization means to change or revise an existing product to meet customers’ special needs. When applying traditional technology in dentistry, it is hard to create customized products as the products are created with a mold and it’s unrealistic for manufacturers to create a new mold for each product. This usually comes with batch production, while with 3D printing, it’s achieved by first scanning the products into a 3D computer model, then by being 3D-printed to match the product exactly. It’s a digital work. That means for any changes on products, we only need to change the digital work. It’s much easier without any additional cost and this customization can help patients speed up their recoveries and reduce their pains.

2. More Precise and Accurate

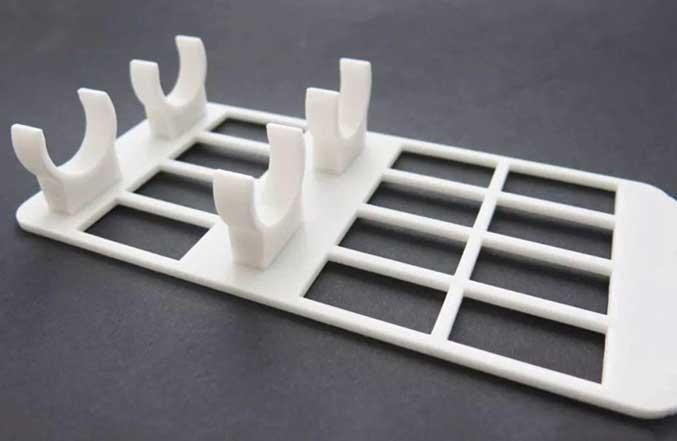

As mentioned above, 3D printing is a digital work, which means it’s computer-controlled and can be customized even with complex structures while in traditional technology, it’s totally relying on mold, so 3D printing can provide a more precise and accurate solution for dentistry application.

3. Cost-effective

3D printing doesn’t rely on any mold and it can be adapted to any product directly only by revising the digital work, while with traditional technology, we need to change the mold to meet customer’s unique needs which may cause unnecessary waste.

4. High-efficiency

3D printing is fast and relatively cheap. You just need to create the computer model by scanning it, then being printed directly. It may only take several days instead of weeks, while with traditional technology, it usually takes a longer time as you need to create additional mold or tools.

5. Labor-saving

With 3D printing, most of the manufacturing processes can be conducted by automation with high efficiency and precision, which, in other words, means less manpower will be needed compared to traditional technology which rely on lots of low-skill jobs to keep their manufacturing operating. As a result, labor costs will be reduced dramatically with 3D printing in dentistry.

Challenges:

1. Job Losses

As the application of 3D printing technology can make manufacturing faster and cheaper and most of the steps can be automated which will save the labor cost dramatically, this will result in job losses as fewer people will be hired in the manufacturing industry.

2. Restricted Size

The size of printed products in dentistry should be restricted to the chamber sizes of the 3D printers. But this challenge will not be an issue anymore as we have developed larger and larger 3D printers to meet various kinds of requirements.

In a word, there will be more advantages after adopting 3D printing in dentistry. For the challenges, the companies are striving hard to overcome them, so as to continue providing perfect solutions for customers. We are sure 3D printing will be widely applied in dentistry soon!

EPLUS 3D in Dentistry

Eplus3D is a Chinese leading manufacturer of AM 3D printers and technology with 30 years of experience, including Metal and SLS/SLA plastic 3d printing solutions, providing professional application solutions for the fields of Aerospace, Automotive, Tooling, Health, Dental, Consumer Goods, Precision Manufacturing, etc.

In early July 2021, Eplus3D installed another EP-M150 Dental Metal 3D Printer in Turkey for a dental lab to produce dental crowns, partial frames, bridges, implants, etc. EP-M150 enables a high material utilization rate and excellent minimum gas consumption.