The process steps of powder bed fusion (PBF) additive manufacturing are as follows:

(1) Apply a layer of powder with a thickness of usually 0.04mm on the forming platform;

(2) The laser beam melts this layer according to the cross-section of the part to be printed;

(3) Repeat steps (1) and (2) according to the molding needs until the entire model is created, and the unmelted powder remains in place but will be removed in subsequent processing steps;

(4) Brush off the part and cut off the base.

The properties of parts produced by powder bed fusion (PBF) are as follows:

(1) Certain porosity, between 1% and 5%;

(2) Anisotropic tensile properties, usually lower in the Z-axis;

(3) Compared with forged parts, lower impact values and fatigue life.

The repairability of parts produced by powder bed fusion (PBF) is as follows:

(1) Depending on the alloy, heat treatment may be required;

(2) Hot isostatic pressing (HIP) process can be used to reduce porosity (<0.2%), improve ductility, fatigue life and impact resistance. Perform precision machining steps according to the blueprint requirements.

Electron beam melting technology (EBM) is an alternative to laser, but it is more expensive and does not have additional benefits for additive manufacturing processes that use stainless steel as raw materials, so it is not a suitable additive manufacturing technology for stainless steel.

The advantages of powder bed fusion (PBF) process include:

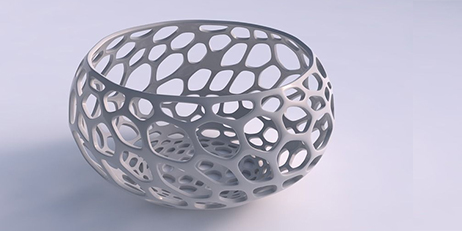

(1) Can shape complex parts that cannot be achieved by other methods;

(2) Form a single part to replace a part made up of multiple components;

(3) Design based on geometry rather than volume to obtain structural strength with less material and lighter weight;

(4) Due to the near-net shape of the part, raw materials are saved;

(5) Replaced physical inventory with a database;

(6) Parts can be produced anywhere, as close to the target location as possible;

(7) Saves inventory and transportation costs, reduces logistics, packaging, and related energy use;

(8) An ideal choice for rapid prototyping.

The disadvantages of the powder bed fusion (PBF) process include:

(1) Expensive powder;

(2) Low deposition rate, slow modeling;

(3) Not competitive in the technical series;

(4) Size is limited by the sealed chamber;

(5) Lower strength in the Z-axis due to anisotropy;

(6) Residual porosity is less than 0.5%;

(7) Impact resistance and fatigue life are lower than forged products;

(8) HIP is expensive and has a long delivery time;

(9) Usually requires precision machining steps (brushing off powder, cutting off from the base, polishing or final processing).

Stainless steel is very suitable for the powder bed fusion (PBF) process, and a range of steel grades can be provided in powder form. New alloys that cannot be produced by traditional methods can be produced by gas atomization technology. Currently, the powder bed fusion (PBF) process of stainless steel is mainly used in many industries such as aerospace, medical, and energy that have strict requirements for part performance.