Auto Exhaust Pipe Printed by Eplus3D EP-M260 Metal 3D Printer

Background:

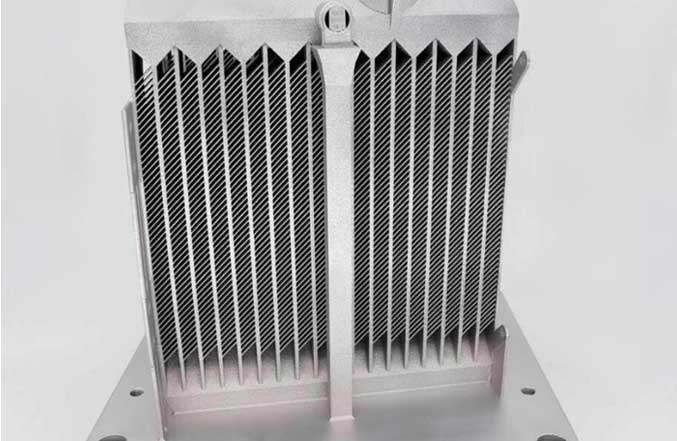

Through the traditional manufacturing method, it normally takes nearly 3 years from design to manufacture the first car from the factory. While additive manufacturing is advantageous not only because of a shorten design and production time, but also building complex structure parts. In recent years, a majority of well-known automotive brands such as BMW, Audi and Volkswagen have set up additive manufacturing centers to integrate the new technologies into their manufacturing workflow.

Introduction:

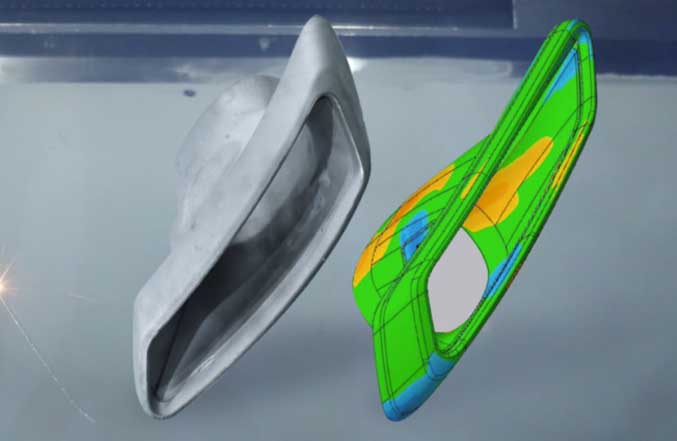

Eplus3D has been working closely with automotive companies and racecar teams, to help them adopt additive manufacturing in order to increase productivity and reduce the cost. One recent case was helping a company to design, produce and test the auto exhaust pipe in a new product development stage by using Eplus3D’s metal powder bed fusion (MPBF) technology and high-precision blue-light 3D scanning and inspection technology.

From 3D Printing to 3D Inspection:

Live video please refer to the following link:https://www.youtube.com/watch?v=HaK-Ola5OZg

Summary:

By taking an additive manufacturing and 3D inspection approach, it decreased the period from design to installation to just one week, resulting in significant reductions in production time, risks and costs. The additional benefits brought by innovative technologies enable new, lightweight design with more freedom, meeting increasing customized demands in automotive industries. Without a doubt, additive manufacturing is going to play a much greater role in the future, Eplus3D is developing technologies of direct printing, batch production of customized parts, and larger parts manufacturing in a wider range of applications.