Introduction

As additive manufacturing continues to evolve, advancements in machines and process parameters are shaping the landscape of the industry. From enhancing stability to optimizing speed, these developments hold the key to unlocking greater capabilities and cost benefits. Exploring some of the critical factors that are driving the change in additive manufacturing, and the implication for businesses seeking to maximize their capability.

Key Principles and Considerations

Some of the fundamental principles guiding the evolution of additive manufacturing is the pursuit of stability in processes. Stability not only ensures consistent quality but also lays the foundation for increased capability. By minimizing variations in printing conditions, manufacturers can achieve higher precision and reliability in their output, enhancing the overall performance of their products.

A key consideration in the pursuit of speed and stability is the choice between deploying more lasers or increasing layer thickness. While both approaches offer potential benefits, each comes with its own set of trade-offs. More lasers enable faster printing speeds by allowing multiple parts to be produced simultaneously. However, this approach requires careful calibration to maintain stability across all laser sources as well as an increased initial investment. On the other hand, increasing layer thickness can expedite the printing process but may compromise the surface finish and dimensional accuracy of the final product. Finding the right balance between these factors is essential for optimizing performance and cost-effectiveness.

The concept of printing fast raises the question: What does it truly mean for cost-benefit analysis? While faster printing speeds can increase productivity and shorten lead times, they also come with associated costs. Higher energy consumption, increased equipment investment, and greater material usage are among the factors that must be considered when assessing the cost-effectiveness of printing fast. Moreover, the trade-offs between speed and quality must be carefully evaluated to ensure that accelerated production does not compromise the overall value proposition of additive manufacturing.

Covering some of the main cost drivers going into the overall AM part for consideration in ROI calculation, what are the production rate requirements and delivery times for these quantities. Build speed from process parameters and machine configuration. Capex (capital cost expenditures) and Opex (operational cost expenditure) associated with the setup and continued cost for your AM system including the materials costs, day to day operations and post processing for the complete production chain.

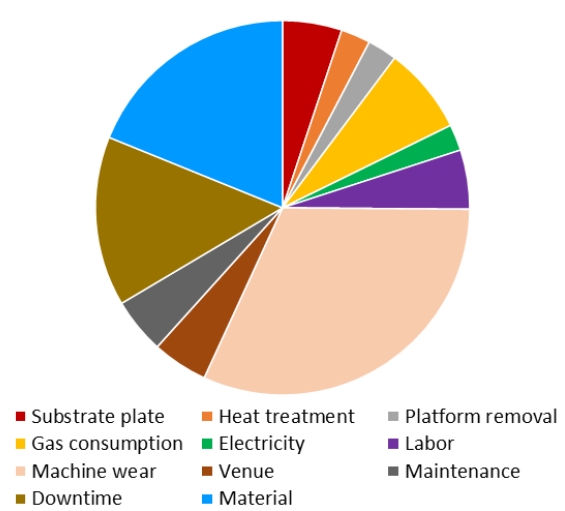

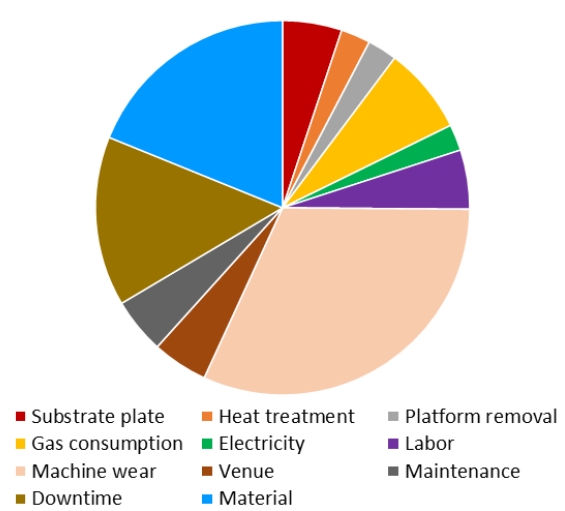

Costing Breakdown

Each item outlined in the pie chart are the costing consideration taken to produce each build. This breakdown of cost is taken directly from the calculation used as part of this study. Highlighting the largest as machine wear and lowest cost as part removal. The material of choice for this study was Aluminium, if a more expensive the material was selected like Titanium or Inconel the cost breakdown show a substantial portion being taken by the material cost. Another factor for this is the part dimension, the parts themselves are design specifically for AM and contain thin walls decreasing the required material to consolidate the parts.

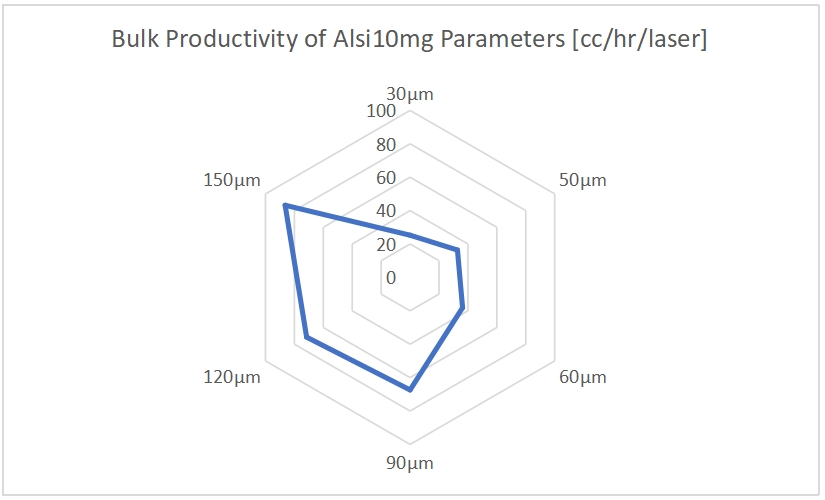

Theoretical and Actual Build Speeds

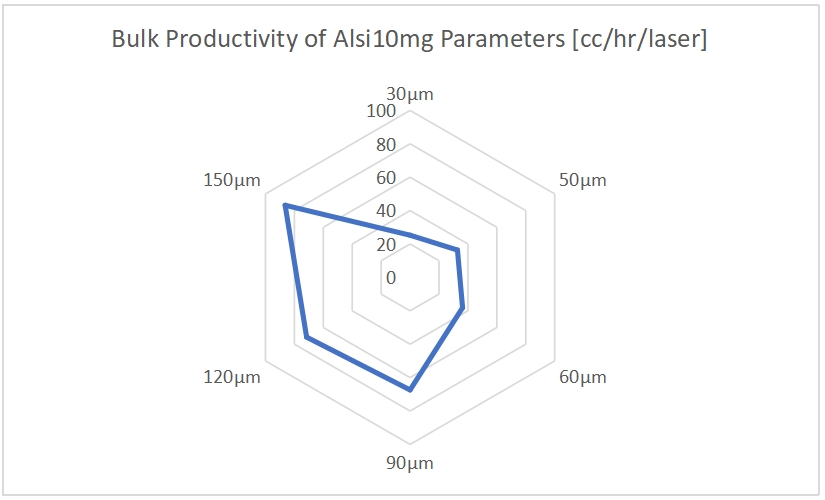

When comparing who has the fastest parameters a common metric to define the performance is the theoretical build speed. A calculated number taking the bulk or in-fill parameters theoretical speed, using the Layer thickness, scanning speed and hatch distance to calculate the volumetric build rate. For the Eplus3D capability for our Aluminium parameters you can see an increase in productivity between the different layer thicknesses as they increase.

This calculated number comes as a good comparator when deciding to use a parameter but will differ from the actual printing speed, as this theoretical number will not take into consideration the change to a part geometry where different process parameters are being applied. For instances down skin regions of the part and % of the AM part that will be printed with borders. When making true part assessments build time estimations should be created to be able to have an accurate representation of the manufacturing time and cost.

Build Time Calculations

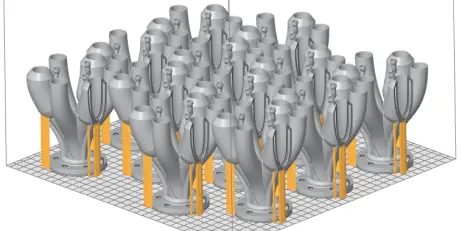

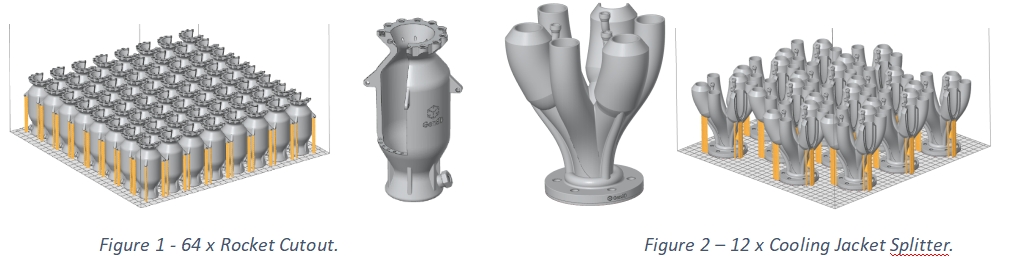

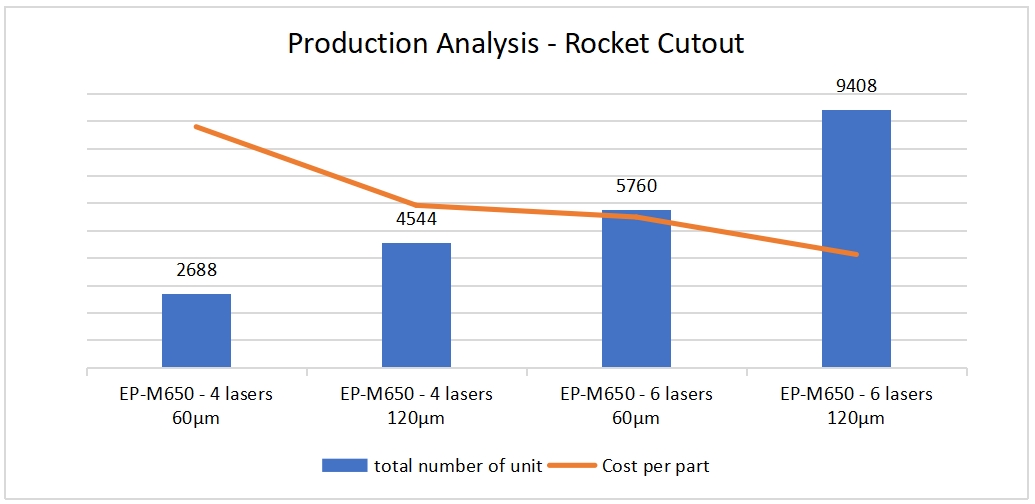

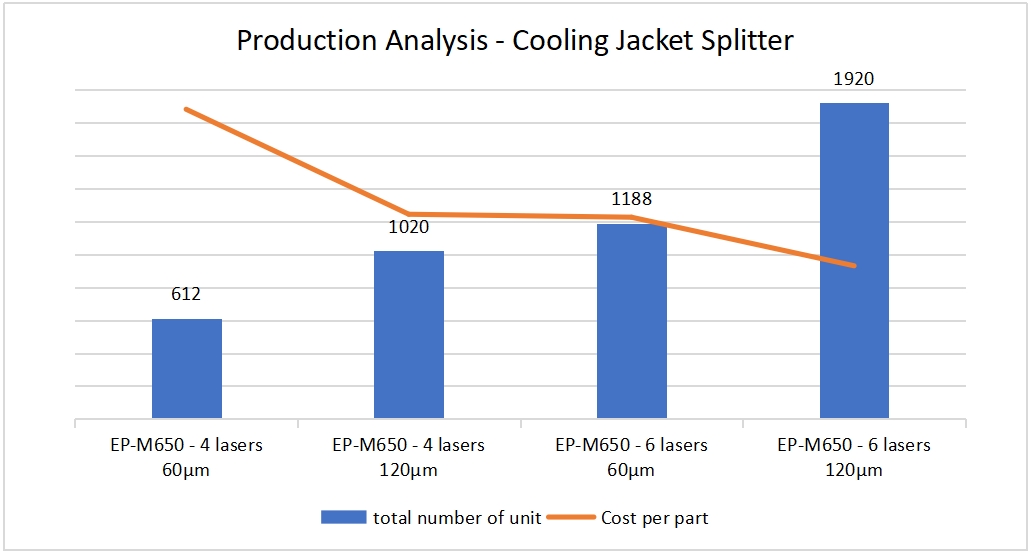

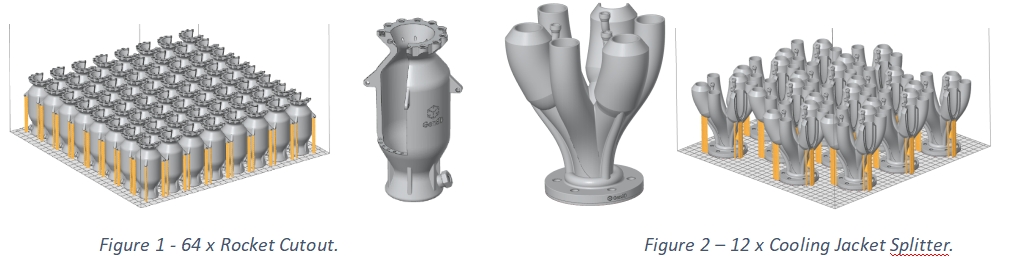

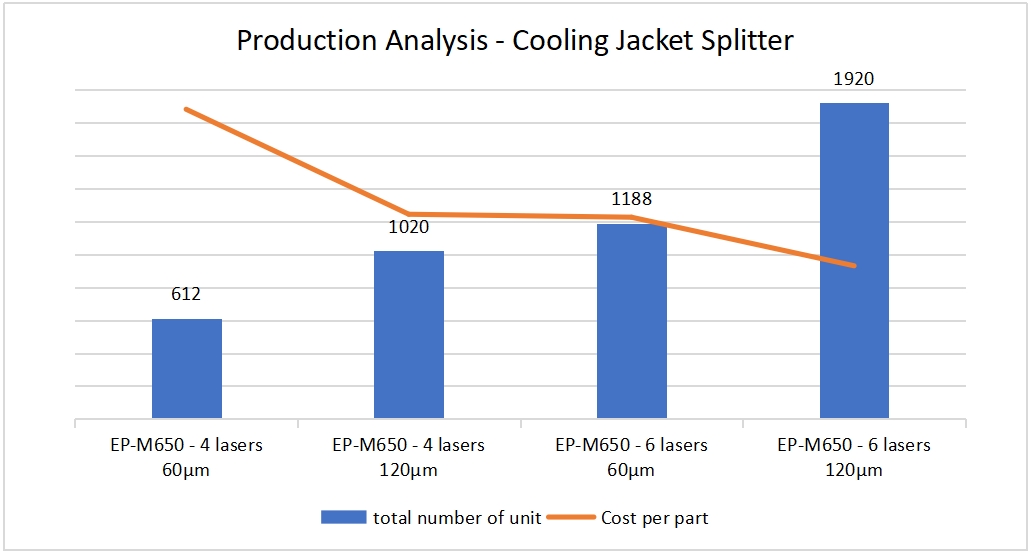

To illustrate the impact of process parameters on production quantity and ROI, let us consider a comparison between a 60µm and a 120µm layer thickness for Alsi10mg. While the 60µm process offers better quality surface finish and dimensional accuracy, it typically requires longer printing times and higher cost. In contrast, the 120µm process can achieve faster printing speeds but may sacrifice some level of detail and precision. Taking the M650 machine configuration and simulating production timing with two configurations, four laser & six laser optical setups. Bringing with it an increased initial investment and assessing the production advantage of using more lasers.

**Gemetry provided by Gen3D**

We conducted a comprehensive cost-benefit analysis by simulating a year-long production run, assuming operations seven days a week across three shifts, with planned maintenance downtime. Our analysis factored in material costs, labour expenses, and equipment maintenance to determine the optimal balance between speed and quality for maximizing ROI.

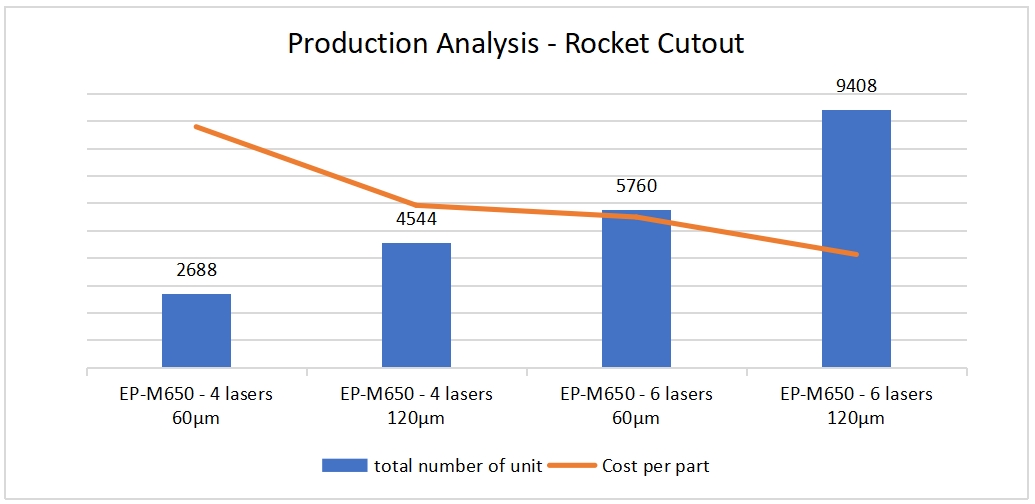

We observed a reduction in cost per part with an increase in layer thickness and the number of lasers. This reduction was more pronounced in the Rocket Cutout application due to its uniform build setup, particularly noticeable with the 6-laser configuration. Conversely, the Cooling Jacket Splitter, with its non-uniform part positioning, showed a lesser impact on overall production costs.

With the already expected trend of decrease in the cost per part with an increase in the processing speed, both comparisons of 60µm vs 120 µm show a smaller effect on the overall cost per part in comparison to increasing the number of lasers in the machine configuration. Showing that not always going for a higher layer thickness is the best approach to increase productivity.

Running at a higher production rate comes with the increased material usage, labour and additional cost associated with increased number of parts per year. Taking the full production cost over a year, including the different machine configurations.

Conclusion

In conclusion, achieving faster additive manufacturing processes demands careful consideration of numerous factors. While speed enhancements can boost productivity and reduce lead times, they entail additional costs and trade-offs. Factors like layer thickness, laser count, part geometry, and build setup all influence the optimal balance between speed, quality, and cost-effectiveness.

The analysis reveals that increasing layer thickness and laser count can expedite production, but their impact on overall cost per part varies based on application type and build configuration. There is no universal approach; each scenario requires a tailored strategy to maximize ROI.

Accelerating production rates also means higher material usage, labour expenses, and infrastructure costs. Businesses must evaluate their capacity to manage these expenses alongside initial investments.

Thorough cost-benefit analyses and consideration of relevant parameters are crucial for informed decision-making in additive manufacturing. Striking the right balance between speed, quality, and cost allows businesses to unleash additive manufacturing's full potential and stay competitive in today's dynamic market.