Additive manufacturing is also known as 3D printing technology, after decades of development, it has become more and more important in various industrial fields. In the automotive field, manufacturers use additive manufacturing technology to reduce production costs, improve prototype quality, and greatly optimize automotive R&D and production processes.

1. Shift from traditional to additive manufacturing

In the traditional way, the automobile industry usually uses wood, foam and other materials to make models and key component prototypes, but such production methods often require a long wait, which reduces the efficiency of product development. But additive manufacturing technology can effectively solve this problem. Using additive manufacturing technology, we only need to create a digital model through CAD software. Then send the model directly to the metal 3D printer, and the printer will print layer by layer according to the digital model. At the same time, according to different performance requirements of the components, 3D printing can use materials with different densities and properties, such as stainless steel, aluminum alloy, maraging steel, etc.. The printed parts can be used for performance testing and can also be used in real production.

2. Size and speed are the critical factors

In the automotive industry, large-size components are the main limiting factor for 3D printing technology, because the integrity of the structure will greatly affect product testing, research and development. Most of the 3D printers currently on the market can only print small & medium size parts. If you want to print large-size components, it is very difficult and it takes a long time.

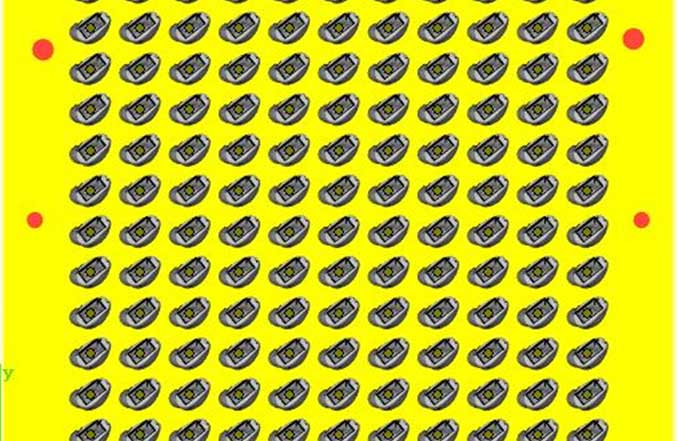

Fortunately, EPLUS3D has developed and manufactured a large-size, high-speed, and reliable metal additive manufacturing system EP-M450. With a large building chamber size of 455*455*500mm³, EP-M450 adopts MPBF(Metal Powder Bed Fusion) technology and becomes a very powerful tool for printing large-size parts with its high performance and high accuracy, and it can provide automobile manufacturers with components of different materials, such as aluminum alloy, nickel alloy, stainless steel, copper alloy, etc.

Check here for Advantages of Metal 3D Printing for Large-scale Products.

Eplus3D metal 3D printer EP-M450

Due to all of these benefits brought by 3D printing, we have to say that automobile manufacturing is inseparable from 3D Printing. With 3D printing technology, automobile manufacturers can produce components more efficiently with lower cost and high precision. This technology will be greatly applied soon!