A 3D printed surgical guide is a placement tool designed according to the principle of reverse engineering, which is made by 3D printing technology. According to CT data of the patient before spine surgery, the 3d model of the spine was reconstructed in CAD software, based on the 3d reconstruction model, the best entry point and access of the pedicle screw were planned, and the optimal length and diameter of the screw were selected. At the same time, according to the anatomical morphology of the spine spinous process, lamina, facet joint, etc., the corresponding model was established in reverse, and the positioning guide channel was designed according to the optimal screw entry channel. The model was fitted with the screw entry channel through the Boolean operation.

Patient information: Thoracic degenerative disease (T9 T10)

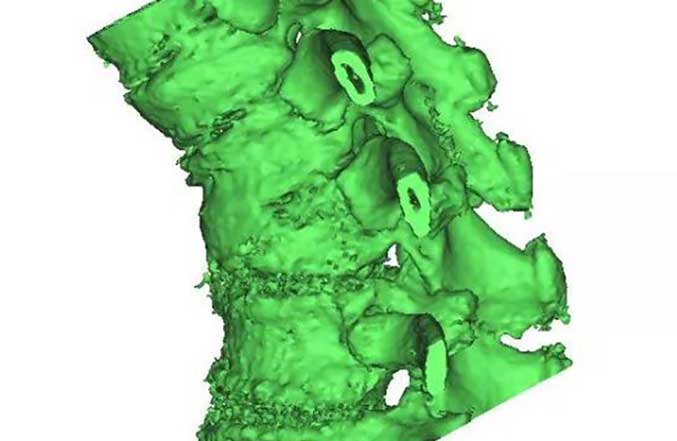

3D reconstruction model of degenerative thoracic vertebrae

Preoperative planning and design

In the design process, the designers used 3d reconstruction system to conduct 3d reverse modeling on the patient’s CT image data, and designed the thoracic pedicle screw system according to the bone morphology of the patient, finally confirming the position, angle and depth of the positioning guide channel. From the engineering point of view, the stability and coordination of the surgical guide were designed and improved.

3d printed surgical guide by SLS technology

The surgical guide and patient’s 1:1 vertebral body model were printed by the SLS 3d printer. The preoperative planning was successfully performed with 3d printed models. Before surgery, the medical-grade nylon material was autoclaved with high-pressure steam, and the surgical guide was attached to the corresponding vertebral posterior bone structure during surgery, so that the screws could be accurately placed on each pedicle along the positioning hole of the positioning guide channel.

Postoperative imaging

3d printed surgical guide can effectively improve the success rate of pedicle screw placement in thoracic and spinal vertebrae. 3d printing technology provides a new treatment approach for complex spine cutting orthopedic surgery such as posterior pedicle screw implantation of cervical vertebra and upper thoracic vertebra, scoliosis protrusion deformity after orthopedic surgery, and chronic thoracolumbar fracture. 3d printing technology not only reduces the operation difficulty and risk, but also reduces the operation time, achieves forward-looking and precision, and provides personalized solutions. It also brings good news for patients to ease their pain.

Eplus3D SLS polymer 3D printers EP-P3850 and EP-P420 are flexible machines for industrial-grade production and research. We also provide advanced processes for industrial SLS 3D printing with the most various polymer materials optional, including polymer material PA12, PA12GF, PA11, PA11CF, etc. With the high performance of mechanical properties for functional test and end products.

In addition to the application of surgical guidelines mentioned above, we are also developing dental, orthopedic and rehabilitation AIDS and other medical application solutions, welcome to discuss with us for more details.