Eplus3D and FAM celebrate a successful one-year partnership, expanding opportunities in the local market through advanced Metal Powder Bed Fusion (MPBFTM) technology.

Eplus3D, a leading manufacturer of metal additive manufacturing equipment, and Fuchshofer Advanced Manufacturing - FAM GmbH, founded by Hannes Fuchshofer, celebrate the one year of partnership to bring the largest Metal PBF Machine to Europe and allow the local market to expand their business strategies based on Metal Powder Bed Fusion (MPBFTM) technology.

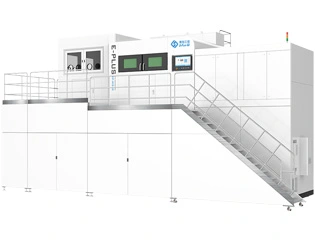

After entering the additive manufacturing industry in the beginning of 2016 with the purchase of their first metal 3D printer, in 2017 FAM conducted deeper research and development of innovative components using the MPBFTM. Over the years, FAM noticed an increased demand for larger parts that exceeded the capabilities of their existed systems. Since 2023, we, Eplus3D, have been collaborating, and our shared goal is to innovate and redefine manufacturing capabilities across Europe. As a result, FAM acquired a large machine, as known as the EP-M650.

“Installed in April 2024, the EP-M650 enables the production of larger, high-quality metal components, designed to meet growing market demands for customization and rapid production, giving us a clear competitive advantage.”

– said Hannes Fuchshofer, CEO, FAM.

“Eplus3D prioritized seamless implementation of the large-format EP-M650 metal printer, with dedicated support from both the German office and headquarters teams.”

– said Enis Jost, Deputy General Manager, Eplus3D GmbH.

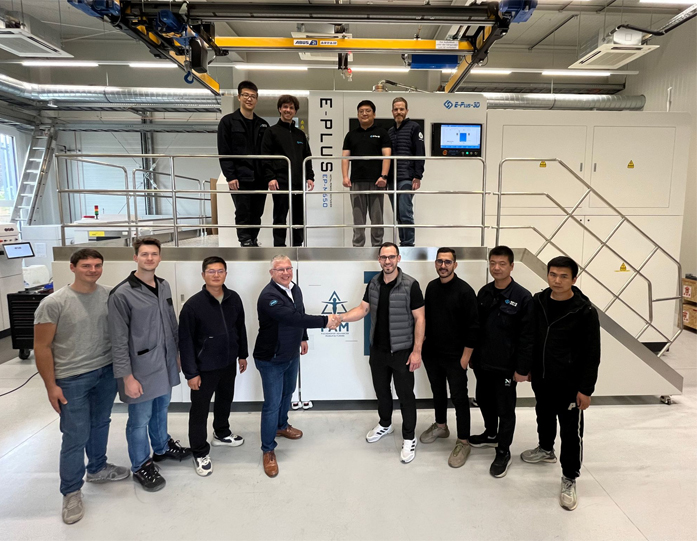

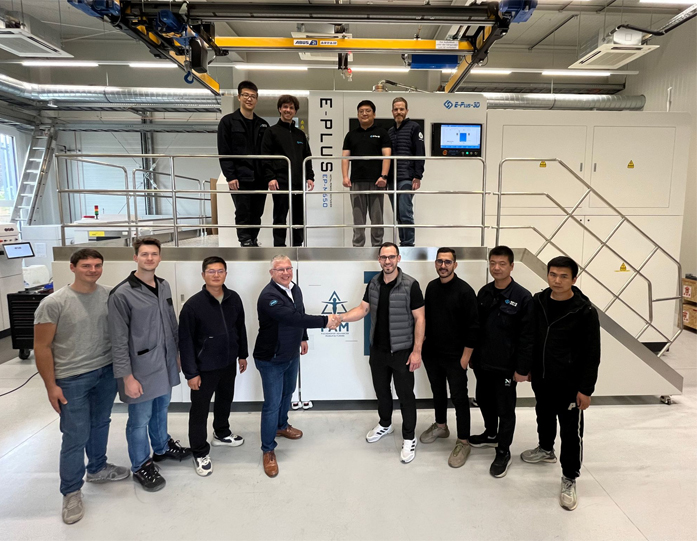

Figure 1 – A Celebration Moment: Eplus3D and FAM Teams Complete the Successful Installation of the EP-M650 Metal 3D Printer at FAM’s Facility.

“The selection of the EP-M650 was driven by FAM´s ample installation space, machine´s unmatched productivity, and innovative features for customized needs. Through the collaboration between Eplus3D and partner´s engineering teams, FAM achieved outstanding results, and Eplus3D reliable local after-sales has been crucial in optimizing their processes and ensuring greater efficiency and precision, high-quality outcomes, optimizing production speed and quality in high-volume scenarios.” said Hannes Fuchshofer, CEO of Fuchshofer Advanced Manufacturing.

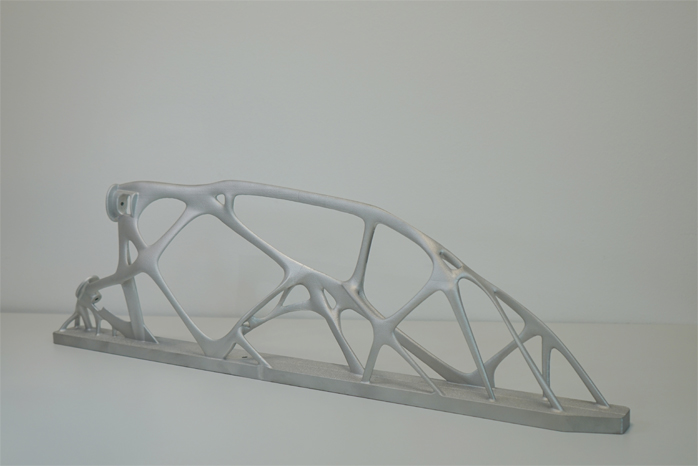

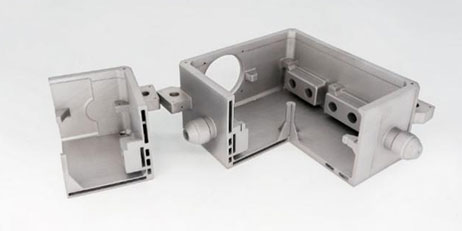

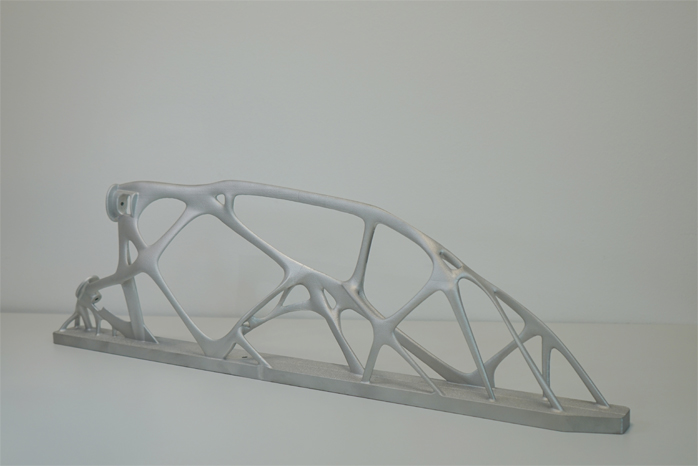

Over the past months, the EP-M650 located in Eibiswald, Austria has served as a real-world showroom for prospective clients, enabling the connection among businesses in need of bigger metal parts that can otherwise be difficult to print with other machines. This collaboration positions FAM as a key player in Europe´s additive manufacturing market, enabling them to produce the first customer components with a size of 830 x 120 x 450 mm that includes Metal Printing and 5-Axis CNC Milling. Within the first six months of the EP-M650’s installation, FAM connected with 32 new prospects, successfully providing tailored solutions to 12 new clients using the advanced capabilities of the EP-M650 system.

Figure 2 - Enis Jost (Eplus3D – left side), Hannes and Gerhard (FAM - middle), and Konrad (HAGI – right side) stand before the EP-M650 Metal 3D Printer, highlighting their successful collaboration in advancing large-scale metal additive manufacturing.

Figure 3 - Underbody Mount Application in Motorsport.

With a foundation of shared success, effective communication, and close collaboration, both Hannes Fuchshofer and Enis Jost are optimistic that the partnership will continue driving new opportunities for mutual growth.

Enis Jost, Deputy General Manager from Eplus3D GmbH, affirms that both companies and multiple departments, such as the engineering and the marketing teams work closely to discuss further opportunities, such as co-exhibiting on Formnext last year and currently in 2024, to further propel each other’s position in the market and grow together.

We, Eplus3D, and Fuchshofer, are confident that this strong and well-based partnership will drive innovation and deliver enhanced value to the market. This partnership will be deepened with the addition of a second system at FAM to broaden the material selection on the available systems to meet the existing requirements of more customers.

For more details we invite you to visit our booth E101, Hall 12.0 at Formnext 2024.

About EP-M650:

The P-M650 is using a large building envelope and 4/6/8 laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as titanium, aluminium and nickel alloy, maraging steel, stainless steel, cobalt chrome and other materials. It is suitable for the direct manufacturing of large-size, high precision and high-performance parts in the aerospace and aviation, semiconductor industry, mechanical engineering, automotive industry, etc.

About FAM:

Founded 30 years ago by Hannes Fuchshofer on his family farm in Eibiswald, Fuchshofer has grown from a small precision machining business into an advanced manufacturing leader. Initially focused on CNC machining, the company now operates 58 cutting-edge CNC centres and offers specialized services such as ultrasonic processing of sensitive materials like ceramics and quartz glass. In 2016, Fuchshofer entered the world of additive manufacturing with the acquisition of its first metal 3D printer, which led to the establishment of Fuchshofer Advanced Manufacturing – FAM GmbH in 2017. Today, FAM GmbH is pushing the boundaries of technology with large-format metal 3D printing solutions both locally and internationally.

Visit: www.fam-3d.at & www.fuchshofer.at

About Eplus3D:

Eplus3D is a professional additive manufacturing equipment manufacturer and application solution provider, especially in the field of metal 3D printers. Since founding the first PBF machine in China in 1993, Eplus3D is engaged in research and development of industrial-grade Additive Manufacturing systems and application technologies using with MPBF™ (Metal Powder Bed Fusion) and PPBF™ (Polymer Powder Bed Fusion) 3D printing technology.

Eplus3D has four facilities in Beijing, Hangzhou, Stuttgart and Houston, with an annual scientific research investment of more than 20% of the revenue with comprehensive invention patents, utility model patents, software copyrights as well as appearance patents. It has made remarkable achievements in the design, process, software, materials and post-processing development for additive manufacturing.

Visit: https://www.eplus3d.com/

APAC Headquarters

Eplus3D Tech Co., Ltd.

Hangzhou, China

P: +86-571-83819589

No. 118 Yanshankong Road, Wenyan, Xiaoshan, Zhejiang, China, 311258

EMEA Region

Eplus3D Tech GmbH

Ludwigsburg, Germany

P: +49-7141-3888118

Pflugfelder Str. 23, 71636 Ludwigsburg, Germany

Americas Region

Eplus3D Tech Inc.

Houston, USA

P: +1 (281) 302-6160

12425 W Airport Blvd, unit 201, Sugar Land, Texas, 77478