From the beginning of year 2020, with the outbreak of the new coronavirus, the medical industry was experiencing special challenges. This did not only reflected in the shortage of medical resources, but also the shortage of various medical supplies. During special period, the quality of medical packaging products was also being severely tested.

We all know that the hygiene and safety of medical drugs are very important, so the sealing performance has become a key position in the packaging of medical products.

The sealing performance of medical plastic bottle caps generally lies on sealing performance of the bottle mouth and cap. The caps have good sealing properties to prevent gas and liquid leakage in the bottle. For plastic bottle caps, sealing performance is an important criterion by evaluating its quality.

Generally speaking, there are three areas where the cap provides the sealing ability, followed by the inner seal of the cap, the outer seal of the cap, and the top seal of the cap.

However, in medical supplies, the caps of small bottles with drug powders such as ampoules are very limited, but it has very strict requirements on the product which must have high tightness. Therefore, the product quality of the sealed cap is particularly important.

This type of injection molded bottle cap has a small volume and a special structure, so the requirements for mold manufacturing are very high, because the quality of the cooling is related to the molding quality of the injection product. With traditional mold making, the waterway is generally processed by machine turning and other methods. However, due to the limitation of the mold structure, the traditional waterway cannot near the product, so it brings with a challenge to the waterway system in the traditional mold manufacturing.

1. In the original scheme, the hot runner flip die has a high temperature and a long cycle;

2. The product size requirements are high, and the product temperature difference should be less than 10 degrees when ejected, which is difficult for ordinary waterways.

In response to the above problems, we share a similar case to make a detailed analysis-medical sealing cover recently.

After using our 3D printing solution, the time for the product to reach the ejection temperature has dropped from the previous 20S to the current 10S, the cooling time has been shortened by nearly 50%, the production efficiency has been greatly improved, and the company's delivery time has surprised Party A. The maximum temperature difference when the product is ejected has dropped from the previous 20°C to the current 8°C, which also meets the manufacturing requirements: the temperature difference during ejection should be <10°C. The temperature difference is greatly reduced, the mold temperature is balanced, the product quality has been significantly improved, and the probability of defects in the injection bottle mouth is very small.

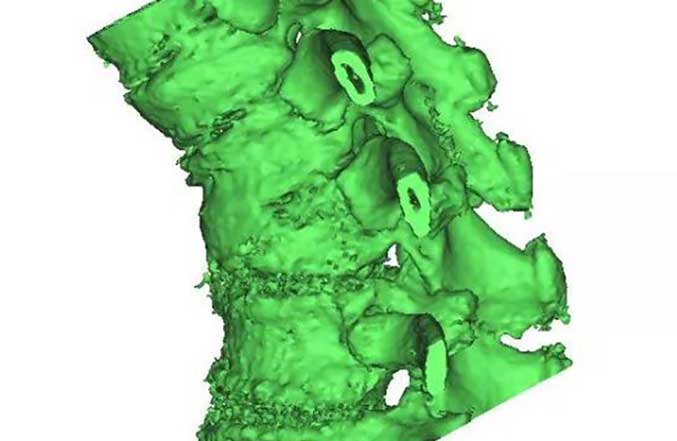

Comparison of mold flow analysis results

According to the customer's feedback data, the accuracy of the mold flow analysis results is also confirmed, and the mold flow analysis diagram is attached below.

Product ejection temperature time

Product temperature